In just over a year, Fenice S.p.A., enterprise based in Valdagno (Vicenza province) fully committed to the development of chemical specialties for the tanning industry, will celebrate its 50th anniversary. The secrets of an ongoing, unstoppable success, described by the president Giuseppe Pisi

Its core business focuses on the development, production and analysis of chemical specialities used in leather finishing, in the manufacturing of footwear and leatherware, in dry cleaning, in renewal of leather garments, an ample range of solutions conceived for the end user of any type of leather goods. This is the distinctive trait boasted by FENICE S.p.A., enterprise based in Valdagno (Vicenza province), specialized, on a gloabal level, in chemistry applied to the tanning sector, – a historic, renowned firm that has been supplying the most prominent fashion brands, praised even by its competitors for its strategic role in the valley’s industrial growth. Since its foundation, FENICE has been paying close attention to market needs, both on a domestic and on an international scale, ready to work side by side with its customers, the latter increasingly competent, demanding and open to dialogue.

Both the website and the social media put in the limelight the corporate philosophy: basic quality, production technicians’ core value, is no longer enough, as other features are now stealing the spotlight, like product polisensuality, a perception that goes beyond appearance, haptic sensation, physical-mechanical characteristics, an ensemble that becomes a texture and that must be designed to astonish the end consumer thanks to the added value it provides. Among the missions pursued by the Veneto-based company, there are the development of a strong brand image worldwide; the promotion of the human resources involved, by ensuring their moral and professional growth as well as the enhancement of their emotional intelligence. Furthermore, it aims at becoming a market leader through constant research, suitable marketing initiatives, the strengthening of organizational, production and distribution skills; at meeting the stakeholders’ expectations concerning the environment, profit and civil society; at nurturing aesthetic properties and an organizationrelated know-how, and at guaranteeing the utmost quality in all its facets.

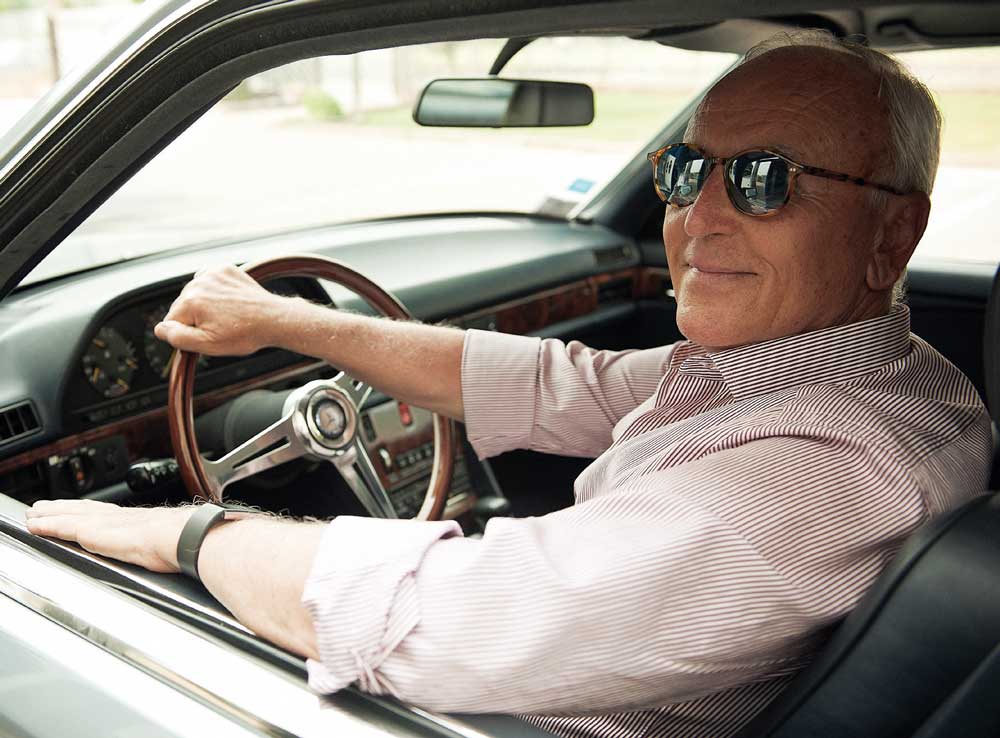

Established in Valdagno on March 2nd, 1973, FENICE S.p.A. has faithfully kept its headquarters in the same location, that is, the beautiful, green Valle dell’Agno, a few kilometers away from the Arzignano tanning district, the latter a pivotal partner, as confirmed by the long-standing synergy developed over the years. Its founder, almost half a century ago, was the entrepreneur Giuseppe Pisi, still at the helm of the company: we met him at the corporate premises.

“In just over a year,” confirmed Pisi, “we are going to celebrate our 50th anniversary, an amazing milestone that makes us proud, especially because we have managed to successfully deal with the majority of the issues we have faced over the years. An ongoing challenge, almost a daily one: in our sector, said strategy has given us the chance to grow and improve. Our purpose is difficult and multi-faceted, it does not solely revolve around the mere production of chemicals, but it contributes to the training of professionals involved in the value chain. The effective and throrough service allows us to work side by side with the customers to promptly solve any issue, whether it be a shoe factory or a manufacturer of living rooms and car upholstery.”

The headquarter of Fenice Spa at Valdagno

How can you describe FENICE products? “In almost fifty years of work and research, the development of our range of articles has exceeded the requirements of structural and functional perfomances, thus putting at the users’ disposal solutions that turn leather into a comprehensive emotional experience. The top-notch technological know-how and the steady attention to related physical-chemical sciences, at the core of the design of our flagship products for finishing and for the leatherware sector, have given us the opportunity to conceive specialties that further widen the corporate catalogue for leather goods. Our technicians boast a high sensitivity when it comes to finishing processes, with a keen eye for certain features such as fullness, softness, elasticity, haptic sensations, reaction to surface light.”

How have you managed to become a benchmark in a secor featuring a fierce competition such as the tanning industry? “Thanks largely to the ability to grasp in advance market trends and demands. As a group, we boast a top-notch structure and in-depth knowledge of work cycles and raw materials, so much so that we can overcome seemingly insuperable obstacles and turn difficulties into new opportunities. Relying on our practical attitude, we keep repeating to customers and partners alike: “Give us a technological challenge and we get to work to fulfill your demands,” For us, a challenge is not a problem, but rather an opportunity and a time for growth, that give the chance to show our expertise.”

What about your relation with the customers? “We support them from the early stages of the production process, showing them the safety and effectiveness of our solutions. Our technicians go visit the enterprises, make samples of the products. More specifically, we deal with the sample-making operations, then proceed with the application, with physicalchemical trials on leather and with the various tests required by specifications. We stay with the customer until the result is absolutely certain.”

How critical is a correct strategy sustainability-wise? “Regarding the regulations that will come into effect in 2022 and in 2023, we are ready, both with the technicians and with the products. We can rely on two technicians, both women, chemistry graduates, who take care of the relationships with the Healthcare Ministry in Rome and with European bodies dealing with safety. We carefully comply with the EU regulations. Over the last few years, chemical enterprises have been actively supporting the tanning industry when it comes to research, to environmental safeguard and to the protection of human health, in addition to rules conformance. When tanneries purchase our products, they know that there will be no issues or surprises. For example, according to EU regulations, by 2023, training courses for the employees that somehow come into contact with isocyanates, are set to become compulsory: Fenice will provide the required support.”

In the last few years, there has been a rise in the demand for articles that use coating as a finishing technique, with an embossed paper called “paper release”. Does Fenice feature a line of products specifically developed with this technology? “FENICE S.p.A. is at the forefront in the development of products aimed at the optimal use of this technology; for quite some time, it has been testing a range of solutions and today is able to provide a technical support that can lead customers to the best results on full-grain leathers, on crusts and on buffed hides for the fashion, furnishing and automotive sectors.”

www.fenice.it

Giuseppe Pisi, CEO of Fenice

FINISHING: TRANSFER TECHNOLOGY WITH RELIABLE PRODUCTS

With regard to TRANFER TECHNOLOGY, this system combines a release paper plant with a spray booth or a roller coater.

Here are the details:

RELEASE PAPER. Release paper is a special embossed paper that bears the negative engraving of the print design that will be transferred to the leather during the process. Before it is coupled with the leather, it requires a sort of “preparation” that comes by using the firm’s specialties, specifically developed for this purpose. It is spread through an embossed cylinder and dried; according to the type of article and to the print size, it can be treated in either one or two coats (using a machine equipped with a single coating head or with two).

LEATHER. In the meantime, leather is treated with a covering basecoat applied by conventional spray or by roller coater.

3-COUPLING. After the “preparation”, leather and paper are coupled by means of a hot plating.

DRYING. The drying of the basecoat applied on leather is only partial and is monitored in order to keep its thermoplastic characteristics, for a better flow-out and an excellent fusion with the film previously formed on the release paper, during the hot plating process. At this point, the article thus obtained is called “fuori macchina” and it will be finished later by spraying a colour coat, with a pigmented coloured resin, followed by any desired effect or finish.

AN AMAZING FINISH. Many companies that have implemented this finishing technology, have achieved remarkable results: the marked improvement of materials, often starting as fourth-grade hides and then becoming the finest one, without using exaggerated covering options and heavy finishing methods. With the synergy between application technology and the bespoke products developed by FENICE S.p.A., it is possible to ensure top-notch finishing performances resulting in first-rate technical and aesthetical properties, set to earn the praise of internationallyrenowned footwear and leatherware brands.