60 years of leadership in the world of spraying systems. We Interviewed Annapaola Trione, Aircom Manager

Castellamonte, a place where the art of spraying blends with precision engineering, is home to a company at the forefront of the industry: Aircom. For years, this company from Turin has specialised in the production of automatic spray guns, carrying on a tradition of excellence and innovation. The ability of Aircom to create precision painting tools is true mastery. The automatic spray guns developed by the company are designed with care and attention to detail, offering superior performance and flawless painting results. Each gun is the result of years of research and development, fueled by the ambition to offer advanced solutions for spraying and finishing professionals. However what makes Aircom so special? The answer lies in the combination of craftsmanship and leading-edge technology. The company skillfully combines Italian craftsmanship with technological innovation, creating products that are true gems of precision. In an increasingly volatile market, Aircom does not just settle for maintaining standards of excellence, but is always looking to the future. The company continues to invest in R&D activities, constantly searching for new solutions to improve the performance of its automatic spray guns. Collaboration with world-renowned technology partners and openness to new ideas and perspectives allow the Turin company to remain at the forefront of the industry. Indeed, the company continues to push the boundaries, driven by a passion for technology and a commitment to offering tools that exceed the expectations of professionals in any sector.

Ms Trione, can you tell us the story of Aircom?

“Aircom is an Italian company with almost sixty years of history. It was founded in 1964 by Giorgio Bria, a technician working in a tannery in Castellamonte, in the province of Turin. Bria, who was in charge of the spraying step in th tannery, was dissatisfied with the quality and price of spray guns imported from abroad. For this reason, he started to design and build his own guns in his garage at home. In 1992, the company was taken over by my father and, after a few years, I started to join him and carry on the business. Since then, we have continued to grow and innovate. We have expanded our product range, which now includes a dozen models of spray guns. In addition, we have developed a range of accessories and services to meet the needs of our clients. We believe that innovation is the key to success. This is why we constantly invest in research and development. Our team of engineers work incessantly to improve our guns and develop new products. In recent years, we have focused our efforts on developing products for the leather sector. This sector is growing rapidly and offers great opportunities for development. We are proud to be a reliable partner for companies in this and related sectors.”

How important is technological innovation for you?

“Innovation is one of the essential pillars of our business strategy. We are constantly investing in new machinery and technology to stay ahead of the latest market trends and to guarantee our customers the best products and services. The latest investment, a new machine for production, was made just before the summer. This investment will allow us to increase our production capacity and improve the quality of our products. Furthermore, we are constantly investing in R&D activities to develop new products and technologies that are more efficient and environmentally friendly. We have recently implemented a new range of products that are more material and emission conscious. These products have been certified for transfer efficiency in Germany, in one of the most prestigious Research Centres. We believe that innovation is the key to success in our industry.”

How does your strategy of expansion into other sectors fit into your business growth plan?

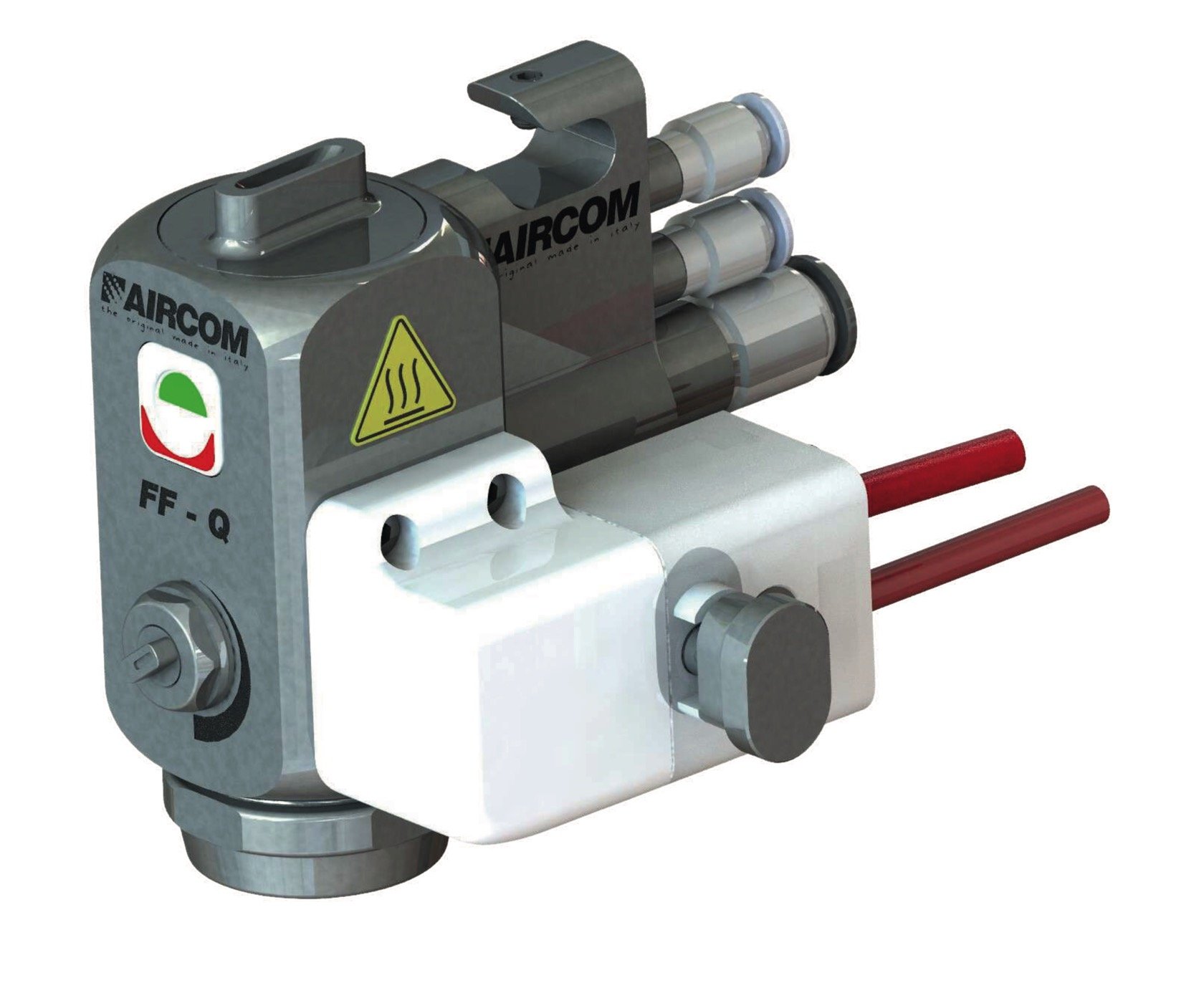

“Our core business is the tannery sector, where we are the market leader. However, we are constantly looking for new growth opportunities. For this reason, we are developing products for other sectors, where our know-how is highly competitive. In particular, we are focusing our efforts on the food sector and the Work&Safety world. At the end of October, we will launch a new spray gun, the Aircom FF, at the IBA trade fair in Munich. This gun is designed to meet the specific needs of the food sector, which is characterised by stringent safety and hygiene requirements, but can be transferred to any other sector where certain requirements are needed. We believe that this new product will allow us to enter a new high-growth market and consolidate our position.”

What features does the new Aircom FF spray gun have?

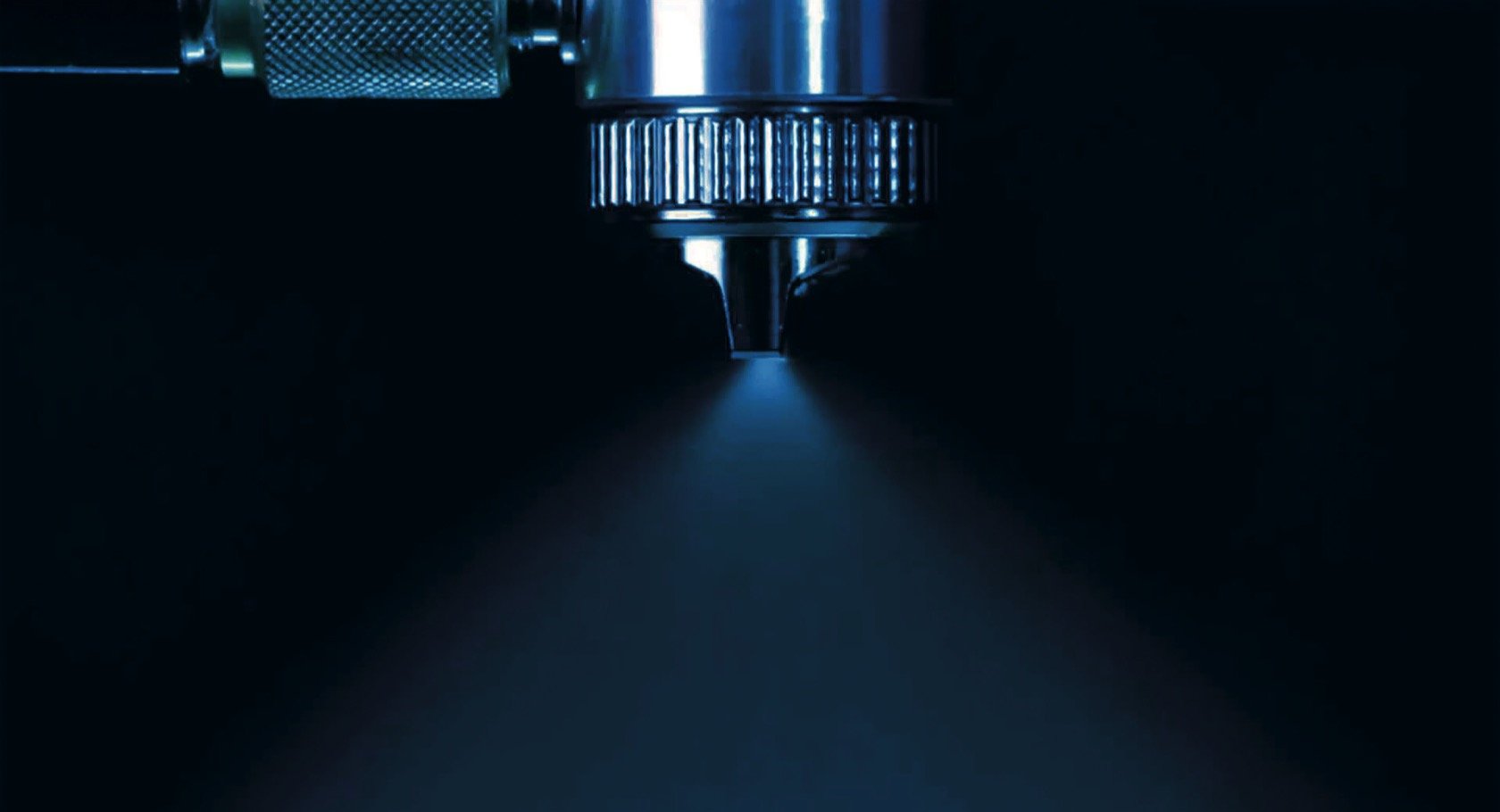

“The new Aircom FF spray gun has a number of innovative features that make it a unique product on the market. First of all, it is very compact, which makes it easy to transport and store. Furthermore, it is completely made of stainless steel, a material that guarantees a long service life and high resistance to corrosion. Another important feature is the possibility of adjustment by means of a solenoid valve. This function allows the spray to open and close much faster than normal, which saves time and material. Finally, it is equipped with a heating accessory for the fixed body. This accessory makes it possible to spray specific products that need to remain liquid, such as varnishes, glues, resins or special release agents. All these features make the Aircom FF an ideal product for a wide range of applications, from the food sector to any industry.”

What new projects are you working on?

“In addition to the existant guns, we are able to carry out specific projects at the request of our clients. This allows us to satisfy every requirement, even the most complex ones. One example is the new product we are developing for a company in the food industry. This company has specific demands for its sector, which require a customised spray gun. Our ability to realise specific projects is one of our strengths. We are able to respond quickly to the demands of our customers and provide them with the products and services they need.”

What are your strong points?

“Our main strengths are engineering expertise and customer service. Our team of engineers is highly qualified and boasts extensive experience in the spraying industry. We are able to design and develop innovative products that meet every need, even the most complex ones. Our work is customer- oriented and committed to providing excellent service, including the supply of spare parts, thanks to a well-stocked warehouse. We are able to provide our customers with the support they need. In addition, we are flexible and ensure prompt delivery times. These strengths allow us to offer our customers a comprehensive and high-quality service.”

Annapaola Trione

The new line of spray guns FF