The program of the Congress was divided into thematic days and in this report, we offer a detailed account of the four-day event, illustrating the main topics and impressions gathered, and placing particular emphasis on the founding themes of the congress: innovation and sustainability.

The title was ‘Towards Sustainability through Innovation’, and from the outset the topical themes of UITIC International Footwear Congress 2023 appeared well defined. Companies must innovate to become sustainable by fully embracing the digital transformation; that was the message of this edition in a nutshell.

Footwear experts from 26 countries around the world convened between Milan and Vigevano last September 2023 for the 21st edition of the congress dedicated to footwear technology organized by UITIC and Assomac in collaboration with Assocalzaturifici. The strong ties that the two cities share with the footwear industry made the selection of Milan and Vigevano as congress venues a natural choice; furthermore, the relevance of Milan, the Lombardy capital, regarding research and innovation, as in the central role of the fashion industry worldwide, aligns perfectly with the congress’ focus on developments in the footwear industry.

UITIC 2023 was a unique opportunity to learn about the innovations and challenges of sustainability in the footwear industry, and the NH Hotel in Assago, the hub of the congress, proved to be a location that lived up to expectations and was easily accessible. Here we listened to the voices of the main players and understood how sustainability is not only a necessity, but above all a source of opportunities. That the matter is fundamental for the future of the sector and requires the collaboration and commitment of all the players involved, to harmonize human needs with the resources of the planet, in a dynamic and virtuous balance that ensures the well-being of present and future generations.

UITIC 2023 begins a day dedicated to visiting factories and institutions as representatives of Made in Italy excellence, with particular reference to the footwear industry.

Program 1 (Supplier) included visits to four companies: Industrie Chimiche Forestali, Tessitura Langè, Tacchificio Villa Cortese and TFL. It was an immersive journey into the world of footwear materials and components, processing and manufacturers, which allowed visitors to experience the quantity, variety and quality of processing carried out, the levels of innovation achieved by footwear suppliers and their crucial importance to this industry.

Program 2 (Inspirational) offered guided visits to a number of companies in the area that are distinguished for their level of technological innovation. It was possible to visit the Kilometro Rosso, the Brembo Brake plant in Stezzano (Bergamo), and the MADE, a Competence Centre offering guidance and support to companies that decide to undertake digital transitions.

By observing significant examples of technological innovation in Italy, visitors were able to understand and appreciate the possibilities it offers and its contribution to the sustainable development of the industry.

Program 3 (Shoe factory), which perhaps because of its proximity to the key sector of the congress was immediately the most popular with participants, included visits to shoe factories: Calzaturificio Roveda, Calzaturificio SeymechamLou and the CIMAC testing laboratory. True excellence in footwear production, which provided a concrete idea of the technological and avant-garde advancement is achieved.

Industrie Chimiche Forestali, a manufacturer of materials and adhesives for footwear, was the first visit the MPA editorial team participated in. Founded in 1918, it is based in Marcallo con Casone (Milan) and is listed on the stock exchange. The President and CEO of the company, Guido Cami, presented the company among the processing areas and, strolling among latest generation of stainless-steel containers, the guests got to know how much capital in terms of investment and processing is involved in the production of high-quality adhesive materials.

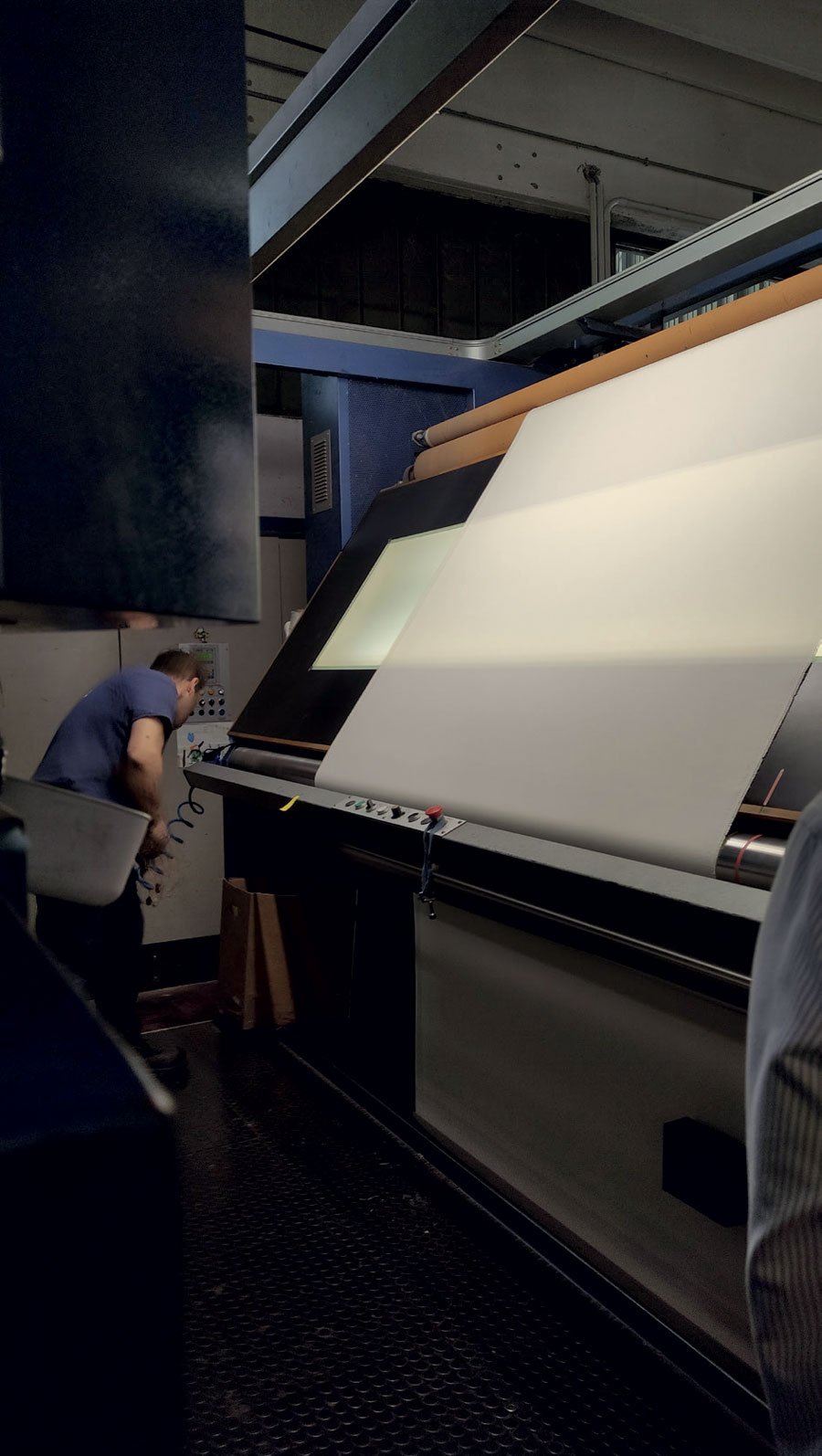

The next visit was to Robecchetto con Induno, to the factory of Tessitura Langè – a brand acquired this year by Industrie Chimiche Forestali, a company of which it was a longstanding supplier – and offered the participants the opportunity to observe the production departments in action and to walk among multicolored rollers and bobbins for winding and storing fabrics and textile materials.

The visits then continued at Tacchificio Villa Cortese, a company that produces shoe components in a futuristic building equipped with state-of-the-art machinery and precision robotics, governed by ultramodern digital screens. It was possible to visit the design office, at that time working on the development of a digital 3D design of heels for high fashion. The visit ended with a short presentation of the company, led by mechanical engineer Majed Al Fawai together with production manager Maurizio Gazzardi.

The last stop of the day was in Buscate, at TFL, a multinational leader in chemicals for the tanning industry present in no less than 90 countries worldwide. The visit to the pilot plant of the tannery in the headquarters of the company was accompanied by an extensive explanation of the preliminary phases of the leather tanning process, the characteristics that differentiate the leathers produced, and the logic behind the choice of materials and processing, each time customized to respond in the most effective way to customer requirements.

Wednesday, September 20th, trade fair day

The day was dedicated to visiting two of the most important leather goods fairs in the world: Simac Tanning Tech and Lineapelle, at the Fieramilano Rho exhibition center. Guided by representatives of Assomac, more than one hundred participants had the opportunity to appreciate the innovations of the fair and learn about the most advanced technologies presented by the exhibitors.

The visit started from Simac, and more precisely from the stand of Lamebo, a manufacturer of blades used for splitting in different leather processing sectors, and those of Tecno21, Ormac and Comelz, manufacturers of machines for shoe factories known for their high quality, cutting-edge technology and refined, modern design; values typical of Made in Italy, of which they are all proud representatives. The exhibitors explained how to use and the specific features of some of the machines, giving practical demonstrations of their use.

After the lunch break, the visit moved on to Lineapelle.

Everything, Everywhere, Every time. This is the message that the trade fair is launching this year for the coming season, the creative input of metamorphosis: to go beyond, to transform, to redefine one’s own nature, in the development of materials, accessories and components in an innovative and sustainable way. A shining yellow circle stands out on the cover of the brochure accompanying the fair as a synonym for a ray of light, again the light of innovation, without boundaries.

In addition to the previews of the coming seasons provided by the various exhibitors, visitors were offered the opportunity to experience a plunge into virtual reality at a stand specially set up by Lineapelle. Wearing headsets, they were able to stroll among the exhibitors in a remote showroom, suspended somewhere in the metaverse; an evocative and dynamic way for designers to show the innovations of their collections.

The day ended with a cocktail reception in the lounge area of the fair, to the overall satisfaction of the representatives of the institutions present. In particular the President of Assomac and Simac Tanning Tech Maria Vittoria Brustia. “It stirs the enthusiasm,” she said, “to see so many people present on these occasions, and even more so to think that, at the same time as Simac, the exhibition of excellence in footwear and leather goods technology, an event of global importance such as UITIC is being held.”

Thursday, September 21st, first day of the Congress

On the stage of the convention centre of the NH Hotel in Assago, in its most traditional form, were some of the major players in the footwear industry from all over the world, each with their proposals, solutions and driving forces, engines for continuing to develop technological ideas, with great, and by now indispensable, attention to our planet and its preservation. The speakers, each starting from his or her own point of view, highlighted how innovation and sustainability are key success values for footwear companies in the current market, and how fundamental they are in responding to the needs of clients. In fact, the choice of supplier is more and more often dependent on ensuring the integrity of the supplier itself, in terms of a sustainable product for both the environment and the worker.

The day of Thursday September the 21st started with an opening ceremony during which representatives of the organising associations welcomed the participants; among others, Yves Morin, departing President of UITIC, Alessandro Spada of Assolombarda, Maria Vittoria Brustia of Assomac, Giovanna Ceolini of Assocalzaturifici, Carmen Arias Castellano of CEC and Fabrizio Nuti of UNIC.

In his speech, Prof. Carlo Alberto Carnevale Maffè, Professor of Strategy at the Bocconi University of Milan, addressed the theme of how product/process innovation is of fundamental importance for the success of companies in a market such as the one today, characterised by new consumer habits, such as the purchase of second-hand clothing (a market that is growing continuously and rapidly), renting clothes, and the preference for sustainable products or recycled materials.

It was then the turn of the manufacturers, who generally agreed on several points. For example, that ISO certification alone is not enough for a company to present itself as an environmentally friendly option in the eyes of the customer. Certification is important, but it must be a starting point, not an achievement. It can attest to the compliance of the company with certain standards, but it cannot alone tell of its history or that of a product. It can guarantee that a product has been made from recycled materials, but say nothing about the sustainability of the production process or the ethical origin of the materials used. To appear truly green in the eyes of the client, companies should take the path of transparency about the methods and materials used. A factory visit, for example, could be a good initial approach, a guided tour in which they explain to the client how ecological innovation finds its way into the processing of their product. Go beyond the concept of mere certification and demonstrate a genuine commitment to sustainability.

Maria José Ferreira, from CTCP – Portuguese Footwear Research Centre, then emphasized how in the footwear sector the biggest impact on the environment is not so much the consumption of the energy used for production as the residual materials and their disposal. Soles and uppers used, at the end of the lifecycle of the shoe, are residues that have to be disposed of and have a significant impact on the environment. Ferreira reminded shoe manufacturers that it is important for a green future to think about these things in advance. Designing, for example, shoes that can be easily separated once they are discarded, designed in advance for a second life, no longer focused to the feet of the customer but towards a disposal center, where the materials can be easily separated, broken down, 100% recycled and put back on the market in a perfect circular economy model. Industrial waste and recycled remnants, upgraded and reused: a process in the making that with the commitment of all can become a reality. “We can do this!”

Many innovative solutions were proposed in a spirit of cooperation and solidarity between the players in the footwear production system, on the path towards a desirable harmonization between the social, economic and environmental dimensions in a shared project of progress. Vittoria Brustia, for example, explained how her company (Brustia Alfameccanica, machine development for the footwear industry), has adhered to the digital revolution that Industry 5.0 entails, with the production of machinery that adopts RFID (Radio Frequency Identification) technology. By means of memory chips inserted inside the shoe, the system makes it possible to identify and monitor each individual article in production. Software analyses the data gathered from the chips, collects it, compares it with the data from other shoes and the parameters entered for the specific product, and generates a report. As the process is fully automated, from this report it is possible, to obtain a massive overview, to predict the amount of final waste, energy consumption and delivery times, and to detect any possible critical issues, without waiting until the end of the production cycle. The company is therefore placed in a position to easily intervene to improve the quality and efficiency of production, reducing waste and environmental impact. Innovative technology, RFID, ensures complete traceability and constant monitoring for each item, and total control of the process in a conscious and sustainable approach.

Guido Polcan is the founder of Meize, a platform providing services and support for the development of creative ideas and solutions, and in his speech, he emphasised the need for companies to evolve their skills and processes on a daily basis. Polcan mentioned some of the most profitable innovations in the field of footwear, focusing in particular on 3D design through which in just a few hours it is possible to create a virtual object that visually has all the characteristics of the material object. In addition to the speed of prototyping and the flexibility of 3D design compared to physical production, there are numerous advantages. There is the possibility of visualizing and communicating a design or a footwear collection in a realistic and complete manner, experimenting with multiple variants of materials, colors and accessories; the reduction in the number of physical samples with time and cost savings; the creation of an online customizer to interact with the customer in a direct manner and offer him greater customization of the product. It is also possible to deconstruct the virtual shoe and 3D print only some of its components, such as soles, uppers or accessories, using innovative and functional materials. Another significant aspect of virtual material testing is the reduction of waste. In fact, the digital approach reduces the need for physical samples and saves energy and natural resources, with a clear reduction in the impact on the environment.

The last stop of the day was in Buscate, at TFL, a multinational leader in chemicals for the tanning industry present in no less than 90 countries worldwide. The visit to the pilot plant of the tannery in the headquarters of the company was accompanied by an extensive explanation of the preliminary phases of the leather tanning process, the characteristics that differentiate the leathers produced, and the logic behind the choice of materials and processing, each time customized to respond in the most effective way to customer requirements.

Gala dinner

The gala dinner was held in the majestic and picturesque setting of the Vigevano Castle. Dating back to the Langobardic era, the castle underwent its transformation into a noble residence by the Visconti and Sforza families during a time of great splendor for Vigevano, when the city represented a crucially important commercial district. After a welcome aperitif in the courtyard, those present were invited to enter the ancient walls of the stables. Here, an elegant atmosphere enveloped in history, made of soft lighting, lanterns and crystals, welcomed the conference guests, who had the opportunity to experience a time of informal dialogue and exchange, tasting refined local dishes and enjoy listening to melodic jazz playing live in the background.

Friday, September 22nd, second day of the Congress

The integration of sustainability in all its diverse aspects is no longer just an option for the global footwear industry, but a pressing necessity. Urgent. Given the change in the attitudes of clients, now more present than ever, aware and attentive to the entire product chain, the adoption of sustainable practices, in addition to the competitiveness factor linked to the reduction of consumption, can represent an attractive factor for companies to their customers. Achieving sustainable production in all its aspects, however, is not always immediate, because it encounters physical and objective difficulties.

On the last day of the UITIC 2023 Congress, all this was discussed, with the stories of success achieved by the participants, the methods to accomplish them, the difficulties encountered and the ways to mitigate them. All proposed as a source of inspiration for the entire sector.

The Congress symbolically ended with the handover of the baton from departing UITIC President Yves Morin to newly elected President Sergio Duilio. Duilio expressed his satisfaction with the success of the event.

“In these two days,” he commented, “there were 45 different speakers, each one bringing his or her point of view with many new insights. They taught us the importance of moving from the material to the immaterial world, because achieving sustainability is impossible without a digital transformation. We became more aware of the crucial role of the consumer, who is now much more sensitive to materials, production processes and their environmental impact. Finally, we learnt that at the center of Industry 5.0 remains the human being, in a human-centric technology concept. This, on the other hand, requires individuals to acquire new skills and to be constantly updated. New professional roles and skills are needed in this changing scenario. Sustainability was also addressed in terms of recycling of waste materials, emphasizing how the search for innovative solutions for the production of more efficient and economical footwear is indispensable. Sustainability is a goal that involves the entire production chain, from machinery manufacturers, to accessories suppliers, to footwear manufacturers, to retailers.

“I am happy and satisfied with the event,” Duilio concluded. “If on your way home you have learned something more than when you came, for me the congress can be considered a success.”