Revomec, headquartered in Trissino (Vicenza province) and specialized in the production and marketing of machines for leather processing, in particular drums and milling drums, enters a 2024 full of challenges but also full of satisfactions, such as the expansion of the operational headquarters with a new warehouse which will increase both the production capacity as well as the overall covered area. The expansion will concern the main headquarters, where the offices, the technical office and the research & development staff were also transferred about a year and a half ago, after a general renovation.

Despite the excitement surrounding this project, innovation does not stop at Revomec, and proceeds at a decisive pace with the updating of the entire range of drums and in particular the Dropless technology, the proven system for humidification in the drum, developed following long research work and which represents an important innovation for the tanning sector.

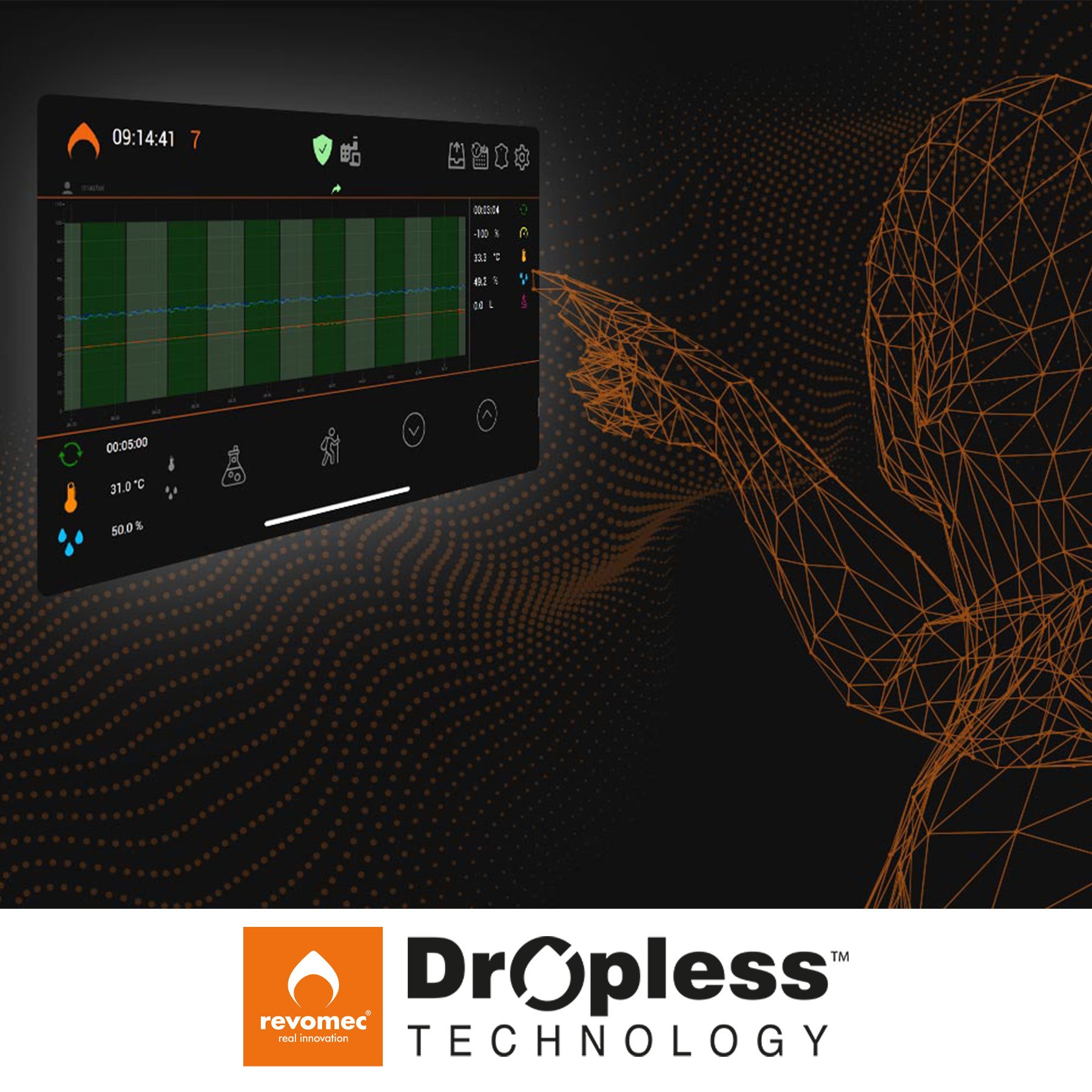

The Dropless 2.0 humidification system is the Revomec system for spotless humidification of leathers. Dropless literally means ‘without a drop’ and avoids any problems with moisture inside the drum from the outset. Version 2.0 is a further upgrade to the technology already presented years ago. Thanks to continuous investment in the R&D department and the further efforts of our team, we have succeeded in improving an already innovative system. Thanks to this version, the machine is able to reach the set values faster, ensuring further savings on the resources used, which were already low with the previous version.

But the advantages of using the new Revomec machinery do not end there. This technology allows better and more precise control of the end result. The flow of humidified air is more regular and uniform, which allows for superior results in terms of the quality of the finished product. In many cases processing times are shortened, and you can see in the graph shown on the display that the trend curve is much more stable and constant. All types of leather can be processed with this special system: from wet-white, to splits, chamois and especially retanned leathers with the new technologies that are very sensitive to water.

This drum is the current ‘top of the range’, but in the meantime the company is working hard to launch new machinery and above all new technologies. Systems have evolved a lot in recent years, also in terms of energy savings and environmental features, to which Revomec has always been attentive right from the very first years of activity.

Manuel Zordan e Fabio Gecchele