The latest trends and technology in the field of technical and non-woven fabrics were the protagonists at the Techtextil fair, where textile innovation meets infinite possibilities; the event is an important point of reference for all operators in the textile sector. Technical textiles will be a keydriver for the future. With their unique characteristics, they represent a vast and fascinating world of innovation for different uses. Ranging from recycled natural fibers to high-performance yarns focusing on sustainability and functionality, they are not simply fabrics, but products designed to meet specific needs in a wide range of applications. In terms of performance, non-woven textiles stand out for their unique properties resulting in innovative solutions for various applications (from clothing to automotive, from hygiene to agriculture), that are versatile and suitable for multiple uses. Non-wowen fabrics boast many characteristics: mechanical resistance to traction, compression, wear, abrasion and cutting, impermeability and breathability to protect from atmospheric agents and favor the release of sweat, thermal insulation, or resistance to high temperatures for use for industrial environments or where there is exposure to intense heat. In addition, they feature flame retardant properties to ensure safety in case of fire, electrical conductivity for electronic applications and in the field of smart textiles and, finally, antibacterial and antimicrobial properties meant for the medical sector and sportswear. In this fascinating and constantly evolving world, technical textiles are those with the highest performance. The technology used for their production plays an important role. Among the latest innovations in the field of sewing, there are many automatic systems on the market for the production of garments, footwear and leather goods, increasingly updated machines and software for decorative and functional embroideries, innovative solutions for textile-bonding of textile systems for the design and automatic cutting of fabrics. There are also solutions for the recovery and reuse of textile waste in various application sectors. This scenario opens up new frontiers for these fabrics, which become indispensable for the development of innovative and sustainable products. Fortune Business Insights market data for the global industry quote a value of almost 226 billion dollars reached in 2023 and foresee a growth to 346.67 billion by 2030.crescita a 346,67 miliardi entro il 2030.

ACCOPPIATURA VIGEVANESE Highly performing technical couplings

ALC TECNOLOGIE ADESIVE Perfection in every detail

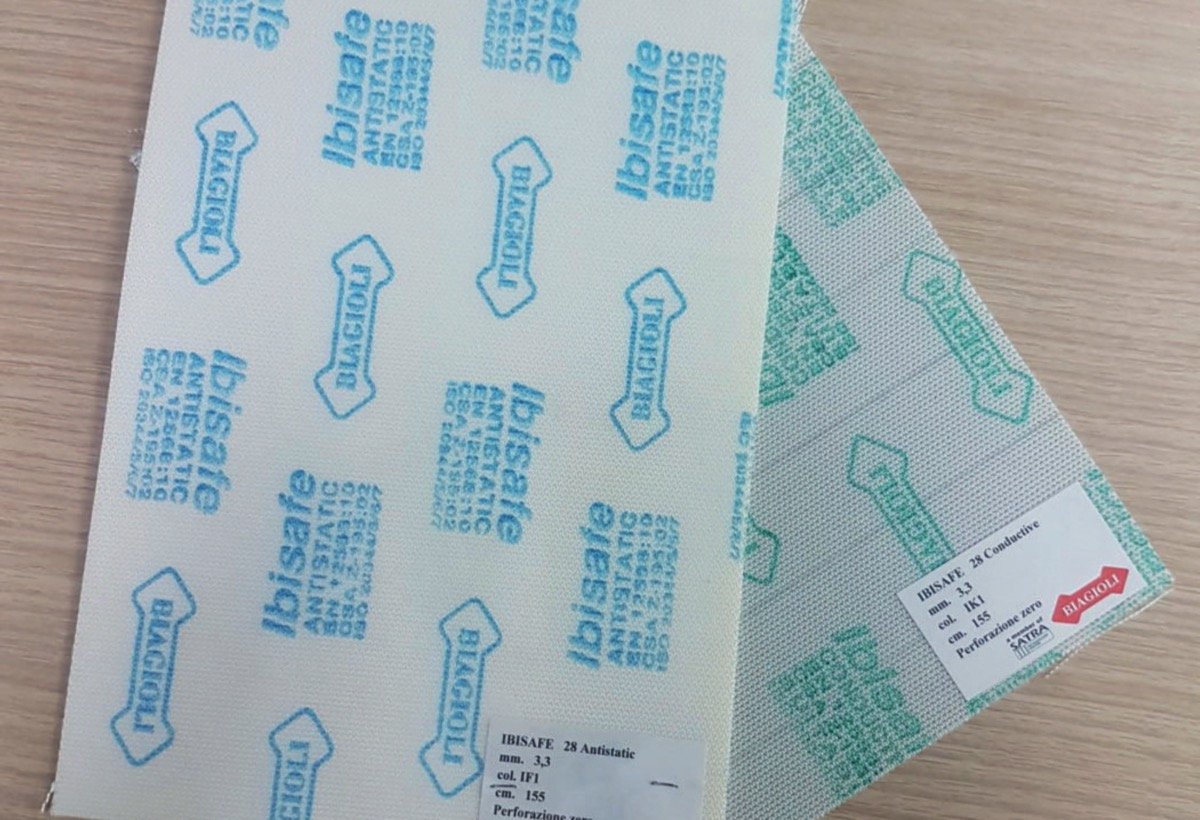

INDUSTRIE BIAGIOLI Non-woven fabric articles DIRECTA PLUS Traditional and graphene-based textile membranes INDUSTRIA CHIMICA MEDITTERANEA Innovation serving the industry IRC Reflective Reflective plastic materials CENTROCOT A center of excellence for textiles and clothing

FF LENZI Tradition and innovation in the textile sector

MATEX Perfection in every detail

VAGOTEX – WINDTEX A combination of excellence in textile production

ROLLMAC Design and construction of textile plants

COS.T.A Technical fabrics

PRANEM Innovative solutions for the textile industry

ICAP-SIRA Specialty chemicals for the textile, nonwovens, adhesives, and coatings sectors

Since 1977, the company has specialized in adhesive and thermo-adhesive coatings and laminations with polyurethane foams, technical fabrics, non-wovens, needle- punched fabrics and many other materials. It operates in a modern facility of over 7200 sq.m. in Mortara (PV). Equipped with a reactive Hot Melt system, which uses a flatbed laminator for the application of “reactive” polyurethanes, it produces breathable, waterproof membranes and extremely high-performance laminations in terms of resistance to temperatures and washing, in addition to barrier film laminations. The maximum width of this system is 228 cm with full-field or breathable spot coating.

A company specializing in innovative solutions, systems and pioneering products for the footwear and leather goods market in the field of thermoplastic polymers, which allow the joining of two surfaces after being melted, pressed and cooled (Hot Melt thermoadhesive). Three brands, Termotac Interlinings specific for clothing, Retifix relating to high-performance industrial adhesives and Retel Car for the automotive sector, provide excellent adhesive systems for different applications.

Tuscan leading company, active in the textiles sector all over the world with products that comply with the highest quality and safety requirements. The whole production is carried out in Italy, in Prato. Regenerated fibers derived from polyester filament residues help reduce waste contributing to circular economy. Continuous investments in research and development, process synergies between modern and highly efficient production lines and machinery innovation have led to a progressive qualitative improvement of the finished product, greater production capacity and operational performance, a significant reduction in energy consumption.

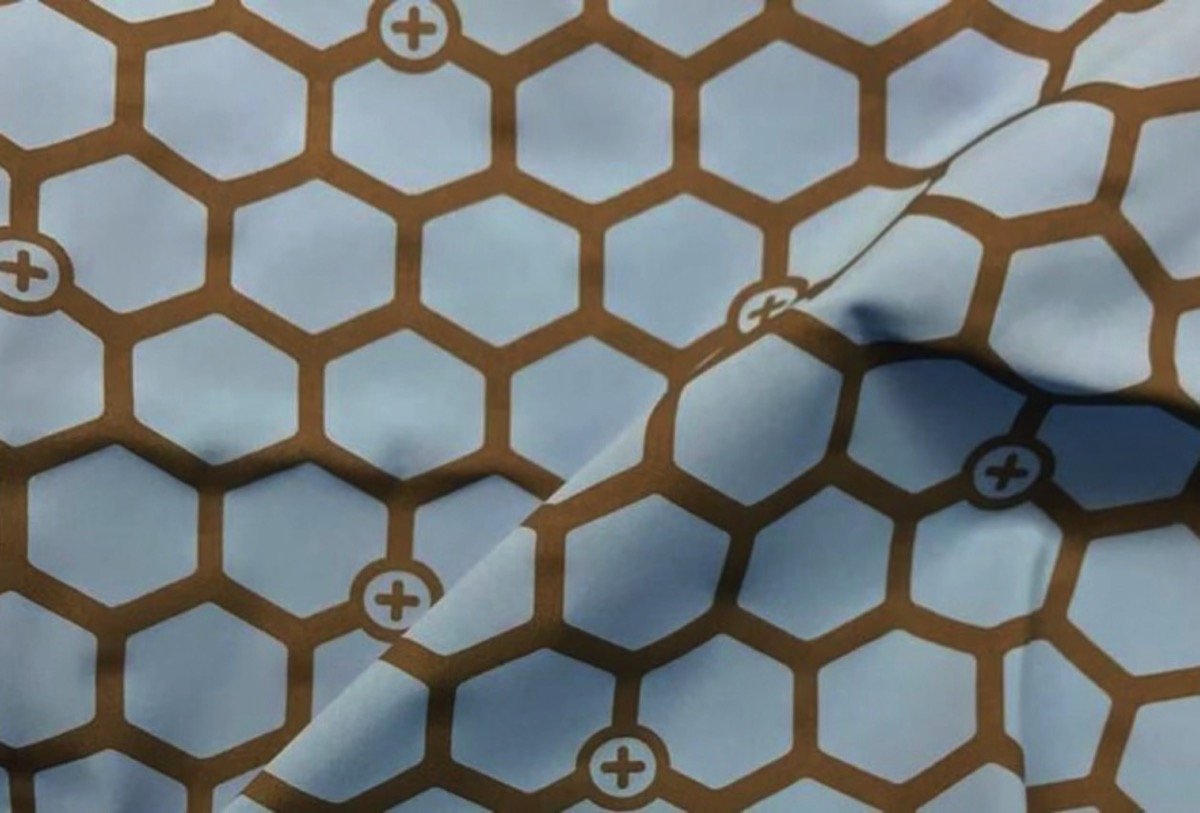

A company with a pioneering vision for the applications of G+® Graphene Plus materials in various industrial sectors, with the Italian headquarters as the center of operations, including research, production, intellectual property, marketing, and sales. The markets where G+® is already in the commercial phase are textiles, environment, composites, elastomers and tires, batteries, and paints. The strategy is mainly to focus on existing products and markets that can be significantly improved with the addition of Directa Plus products. The company collaborates with key partners, benefiting from their market knowledge, a strong reputation, and performing sales channels. An internal advanced development area consists of several laboratories to test and certify the performance quality of all products and to provide technical support to partners.

Italian chemical company based in Naples, founded in 1956, boasting over 60 years of experience in the production of a wide range of chemical products, including films for flexible packaging, labels and industrial applications, adhesives for footwear, leather goods, and for other industries, components for soles, heels, and other footwear components. Industria Chimica Mediterranea, with the support of experienced professionals with a deep knowledge of the chemical sector, is committed to sustainability and offers a line of eco-friendly products made with recycled and renewable materials. taking advantage form the synergy between different technologies for creating customized products with high performance content, it is able to provide technical solutions in highly demanding markets.

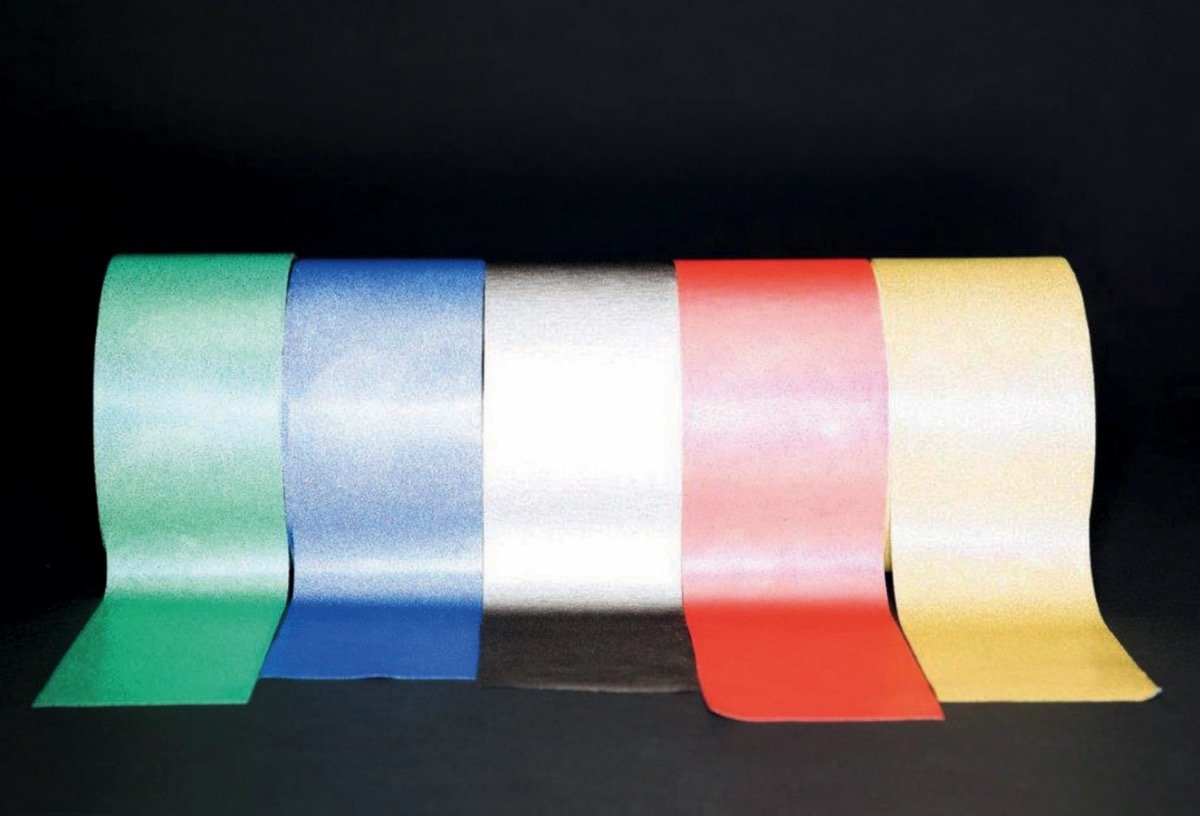

Italian company based in Soliera (Modena), specializing in the production of high-quality reflective materials. Founded in 1978, it boasts extensive experience in creating innovative solutions for different applications, with the aim of improving safety and visibility in various contexts, including safety clothing: jackets, trousers, shoes, and accessories with reflective materials to ensure greater visibility for users in low-light conditions, reducing the risk of accidents. IRC Reflective places quality at the center of its commitment by using certified materials: all products are made with certified materials and meet the most stringent safety standards.

Centrocot S.p.A., based in Busto Arsizio (Varese), born in 1987 to develop the textile sector, is a leading service, testing and certification company for the textile industry boasting 2,132 laboratory tests, 774 tests accredited by ACCREDIA – the national body designated by the Italian government to certify the competence and independence of certification bodies -, more than 1,600 OEKO-TEX® certificates and more than 1,500 certificates on protective devices. Great attention has always been paid to Research and Innovation for which a specific space of over 1000 sqm has recently been expanded in the Malpensafiere area: the MultiLAB with its instruments, a multi-sector experimental laboratory supporting companies looking for new innovation challenges linked to sustainability and the circular economy. Centrocot focuses on innovative materials for the development of new eco-sustainable and bio-degradable materials, new production processes for the development of new sustainability approaches, innovative production processes for the research, development and experimentation of new recycling products and applications.

For over 120 years this Tuscan company has been a market leader in”intelligent fabrics” development, innovative materials that guarantee high-level technological performance. Thanks to a constant development, Lenzi Egisto® offers tailor- made and extremely revolutionary solutions for the sector, resulting in significant advantages for all customers. In addition to a classic line, Lenzi Egisto® develops projects in collaboration with its customers, targeted solutions resulting from technology, innovation and research in which it specializes with technologically advanced fibers and raw materials such as polyamide, polyester and polyurethane. Looking to the future, FF Lenzi is the ideal partner for companies in the textile sector seeking innovation, quality, and reliability.

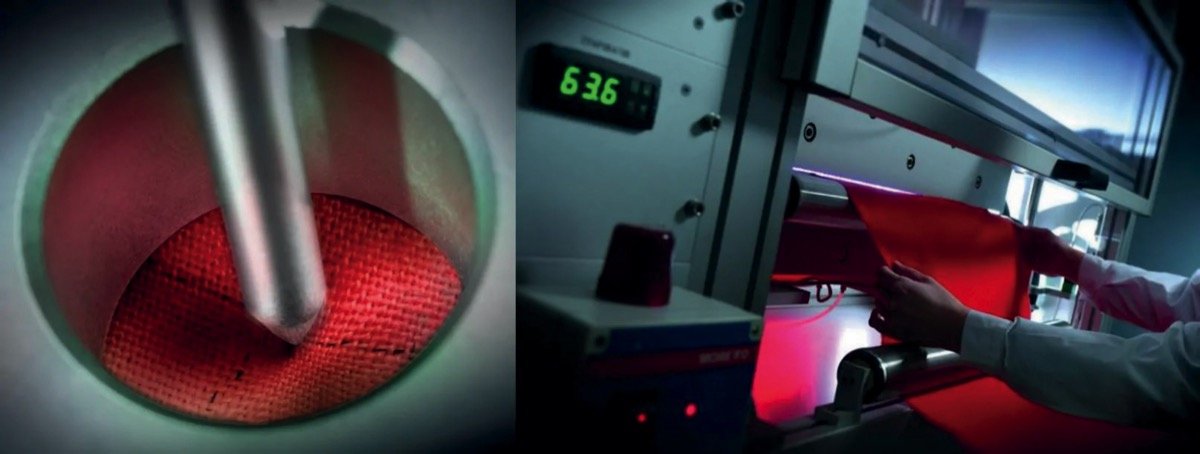

Machines and systems for roll-to-roll industrial processes on paper, plastic films, fabrics, and non- wovens: a wide range of solutions and technologies for the finishing of bovine crusts, the production of technical fabrics, and synthetic leather, particularly for the automotive sector. Solvent-based and non- solvent-based resins are used in these processes. The product range spans from pilot machines dedicated to research and development/small productions to systems with very high production capacity.ma capacità produttiva.

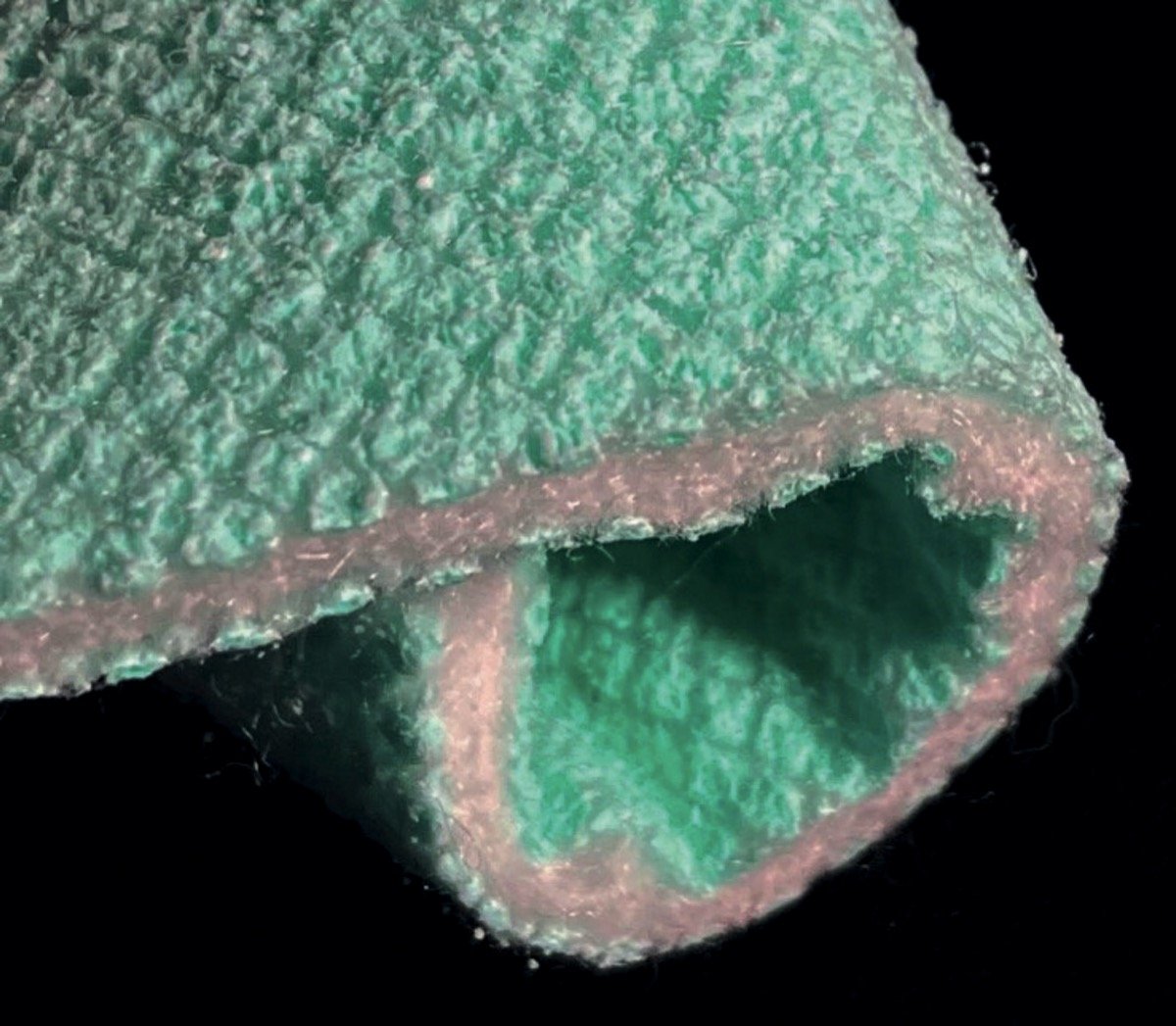

Founded in the 80s in Vago di Lavagno, in the province of Verona, a fertile area for industry and trade, Vagotex Windtex spa is a leader in the sector of technical membranes for laminating and laminating fabrics for technical and sports clothing and footwear. Innovation, competence and variety of solutions represent the strength of this company. Years of consolidated experience in the field of lamination combined with continuous research and development allow to constantly improve materials and production techniques and to offer tailor-made products, made according to the specific needs of each single customer. The 100% in house production allows Vagotex Windtex to maintain direct control over the entire production process and to always offer maximum quality and flexibility.

Founded in 1965, ROLLMAC boasts over 55 years of experience in the sector and stands out for reliability, innovation and customer focus. An Italian excellence in the global textile scene and a reliable partner for textile companies looking for high quality plants, customized solutions and best service. The range of products offered is wide and includes machines and components for textile coating, a sector in which the company positions itself in a niche, bordering on finishing. But, in addition to textile finishing, Rollmac also dedicates itself to the finishing of technical fabrics and synthetic materials, further market niches that always fall within the textile sector. Furthermore, the company offers a wide range of products, from production lines to components and laboratory equipment, to completely serve the textile industry.

The impregnation of fiberglass, carbon and Kevlar, starting from both fabrics and filaments, makes Cos.t.a. a leader in the preparation of pre-impregnated fibre-reinforced composite materials. The technical coupling performed in Wet or Dry Process, One-Coat or Hot Melt expands the range of coupling machines. This company, which also operates in the tanning sector, is a leader in finishing in the automotive sector.

Prato, a city renowned for its textile tradition, is the beating heart of Pranem, a cutting-edge company in the footwear sector. Its commitment to promoting the use of recovered fibers and the recycling of textile processing is unique. Through rigorous selection and accurate workmanship, Pranem transforms waste materials into articles for linings, midsoles and insoles. This sustainable approach reduces environmental impact and even contributes to the creation of high-quality products. Thanks to a team of highly qualified researchers and designers, the company has developed innovative materials that guarantee superior comfort, resistance and safety. The combination of sustainable fabrics and cutting-edge technologies has allowed this company to create components that combine functionality and style, satisfying the needs of professionals from different sectors. With its dedication to sustainability and innovation, Pranem stands out as an inspiring model for companies in the sector, demonstrating that industrial progress and environmental protection can go hand in hand.

Icap-Sira, with headquarters in Parabiago and factories in Barberino del Mugello, Casorezzo and San Mauro Torinese, is a company specializing in the production of chemical products for various industrial applications. Founded in 1946, the company has a long history of innovation and development of cutting-edge synthetic and formulated products. Thanks to its strong commitment to environmental sustainability, the company has adopted a series of sustainable practices in all production processes, reducing the environmental impact. Equipped with a modern research and development laboratory where a team is constantly at work to develop new products and improve existing ones, Icap-Sira also collaborates with universities to co-develop products with better application and environmental performances. The constant attention to regulatory developments and market demands represents the key to its success in this sector.