Thanks to a high-profile know-how, to a long-standing experience and to steady investments in state-of-the-art technologies, Alba&N has managed to win over a significant market share, growing into a reliable partner for the footwear industry.

Expertise, professionalism, a constant drive to innovation and research: Alba Shoes Group and the Alba&n. brand provide the clientele with an ample range of shoes – fashion, safety and work models -, made with top-quality materials and components, able to ensure top-notch performances, the utmost comfort and prime safety standards. A steady commitment that has helped the group become a reference point for the whole footwear sector, praised by several internationally renowned brands as well. Teuta Pistolja, sole director, explained in depth the enterprise’s strengths and goals.

Alba&n’s team: in the middle (wearing red), Teuta Pistolja and, next to her on the right, Nikolin Lleishi, Alba Shoes Group’s founder

When was the firm established? Alba Shoes Group was founded in Albania in 1993, when the first facility specialized in the production of uppers was opened in Lac. As for Alba&n., on the other hand, it was established in 2006. Over the years, the demand has grown more and more, so much so that we have kicked off some partnerships with prominent international brands. At the beginning, we focused on the fashion sector, thus manufacturing uppers for all type of footwear, men’s, women’s, children’s and sports shoes.

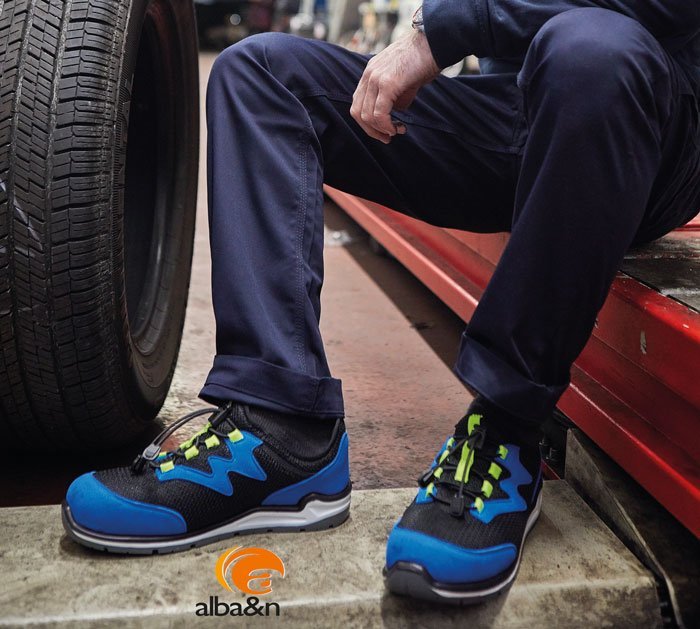

When did you start dealing with the safety footwear sector? After 2000. First of all, we specialized in the upper manufacturing and assembly processes, because work shoes require certain skills and, later on, once we understood that we were highly interested in this field, we turned to the development of soles as well. The first models featured a basic style. In 2007, in a matter of months, we launched the whole range, while, in 2008, we attended for the first time the Expo Protection exhibition in Paris and A+A in Düsseldorf. Since 2010, there has been a slight change in attitude: still focused on the production of safety shoes, yet preferring a sporty, innovative design with a fashionable touch. Be that as it may, ours was undoubtedly the first company to ever showcase sneakers during a trade show.

As for production processes, what are your key strengths? Flexibility, both production- and service-wise, and customization: we do not have a high minimum order rate and we do everything in our power to meet the customers’ requirements. For this reason, we aim at supplying models tailored to the clientele’s specific demands. We can rely on the support of the in-house pattern-making department, based in our Italian plant, and we manage to provide samples. quickly Moreover, we have an in-house laboratory equipped with cutting-edge machinery and tools so as to carry out sample tests on both raw materials’ batches and on the finished product, thus guaranteeing first-rate quality and safety standards.

Innovation: what is the role played by this pivotal concept technology- and materials-wise? Our factories based in Italy and Albania are modern, state-of-the-art facilities, provided with cutting-edge technologies with a low environmental impact and boasting reduced consumption levels. Concerning injection machines and moulds, we turn to the best Italian manufacturers. As a matter of fact, we have been investing significant resources and we are satisfied with the results. As for materials, on the other hand, we are thoroughly committed to research activities. Said projects do not always turn into reality; however, we strive to develop something new every year. Furthermore, the synergy with the district is very fruitful, given that we often take heed of local suppliers’ suggestions.

What are your reference markets? Besides Italy, the majority of our customers is based in Europe. However, we have been gaining a strong foothold in other markets as well, especially Arab countries, Latin America and Africa.

In your opinion, is it necessary to foster a new safety footwear culture? Absolutely. We should raise people’s awareness. When you think about it, we are ready to spend a lot of money on a pair of shoes we seldom wear, while we insist on saving as much as possible when it comes to models conceived to be used for 10/12 hours a day. I have noticed that people choose to wear our shoes even in their leisure time, after the working day. The surprising thing is that, despite their lower price, safety footwear and workwear are produced with incredibly innovative materials, subject to way stricter tests compared to the fashion sector. The brand name and marketing activities are certainly important, yet work is an integral part of our life: therefore, we can’t afford to underestimate key concepts such as wellbeing, occupational health and safety.

www.albaen.it