This is a snapshot of the Altofare Group, an Italian holding company specializing in the production of accessories and high-end components for major international luxury brands. A platform built on the desire to create a system to compete on the market

Altofare is an Italian group specializing in the production of accessories and finishes for large companies operating in the luxury market. The project is supported by White Bridge Investments, a private holding company, i.e. composed of families of industrialists who together define strategies and identify the most interesting markets in for investment. The new platform brings together under one roof a range of industrialized high level artisanal companies with different expertise but common values, without altering their distinctive features. In support of a business that responds promptly and efficiently to customer needs, it offers them new infrastructures and technologies, trained personnel, digitization of processes and an integrated Industry 4.0 system for all Group units.

At Lineapelle, Engineer Davide Aicardi, Group Chief Executive Officer of Altofare, illustrates the goals of this project, based on ‘working as a system’ mindset and aimed at enhancing the yet unexpressed capacities and potentials of a sector whose value is known and recognized worldwide.

Engineer Aicardi, please tell us first about yourself.

“I am an expert in business transformation and post-merger integration, as well as specializing in digitization, process efficiency and operations improvement. After graduating with an honors degree in civil engineering from the University of Genoa, I lived in London and dedicated myself to strategic management consulting for large multinationals for ten years. Then began, somewhat by chance, projects in the fashion world – Burberry, Ermenegildo Zegna – where I worked on supply chain, operations, digital improvement and integration, merchandising model creation, customer experience. Then came the time at Michael Kors (Capri Holding), where I was Director of Business Transformation and IT Lead for the EMEA market (acronym for Europe, Middle East and Africa, ed.) following the transformation of the American brand over the years. From there I moved on to work for the US holding company Hanes Brands – best known in Europe through the Champion brand – as Chief Digital and Transformation Officer for the Group as well as Vice President EMEA Technology.

Finally, the meeting, also by chance, with the owner of the White Bridge Investments fund, a Milan-based investment holding company with private participation. The understanding between us was great, immediately. The opportunities for development, the ideas, and potential for growth were enormous. I accepted his proposal and here I am.”

So Altofare Group was founded by an encounter.

“It is an ambitious and interesting project. The theme of integration and structural organization of the value chain is in line with me. I am following the operational model we have just designed: a series of acquisitions characterized by the strong horizontal integration of the companies belonging to the Group and their close commercial synergy. In the last two years we have created a strong core, eleven Italian companies that are highly specialized and a point of reference in the production of highly manufactured and innovative accessories and finishes for the major international luxury brands: Gruppo OBI, Industrie Testi, Tacchificio Monti, Lampa, Griste, OBI IAB and Conti & Vannelli, CDC Luxury Chains, P.F. Pressofusioni Fiorentine and SCAF, and Forza Giovane Art. The idea is to keep on growing, even if not as ‘aggressively’ as we have done so far.”

From Lombardy to Tuscany, from Emilia Romagna to Veneto and Marche. What is the added value of your group compared to other supply chain operations working in the same territory?

“It should not be read it in terms of territory, but in terms of product type. We are moving in a different way compared to other supply chain operations that have taken place in recent years, proposing a longer-term and broader project. White Bridge Investment operates differently from the usual private equity, which is a financial vehicle with predetermined exit cycles. In our case we are talking about a very disjointed supply chain of medium-small companies that need to combine specific technical skills and business relationships with managerial skills.

We have studied and created ‘at the table’ an integrated model between a team of managers who joined the Group with me and a class of entrepreneurs with strong know-how that cannot be disregarded, who will continue to develop their product while maintaining their own operational role. The companies we have identified are all strongly connected and complementary, and fit perfectly with our strategy and value chain model.

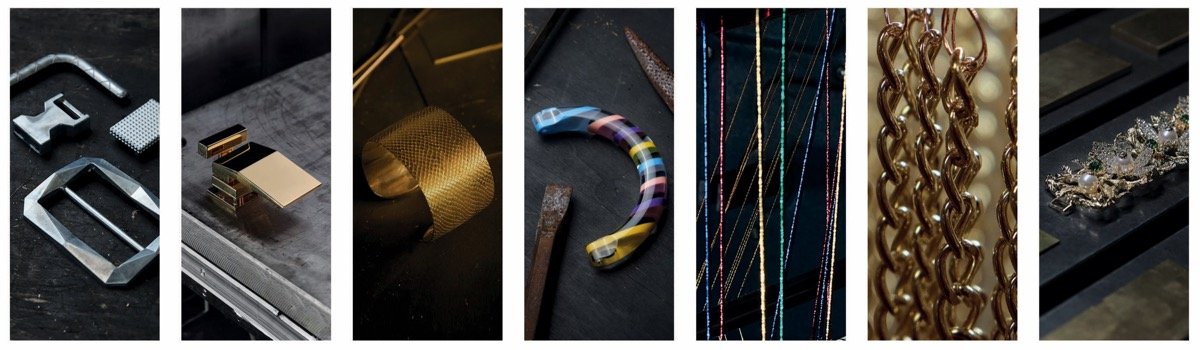

We have a range of materials and processing solutions within the Group that is incredible! At Lineapelle, we developed a representative sample of all our techniques, where each of the companies dealt with a certain aspect within its area of expertise. Many of the skills and potential of the companies in the Group are still unexplored and my task is to ‘bring them out’, to show the brands what we can achieve.”

What is your most ambitious goal in terms of process innovation?

“We are making huge industrial investments. Those of governance are staff functions to support the Altofare Group companies, aimed at creating their complete digitization, a shared supply chain, a single central finance, IT integration and what I call material innovation. All aimed at facilitating efficiency, productivity and agility of the entire platform for an extreme speed of response to fashion and luxury needs.

Production activities will tend to remain in their respective territories, except for old factories whose renovation would be uneconomical. In this regard, we have initiated an important investment in Prato. We are redeveloping the warehouses of a former weaving mill, a unique structure of industrial architecture, very large and very beautiful, which will include a number of businesses by integrating their production cycle, but respecting their single identities. It is a project along the lines of the Altofare set-up at Lineapelle: each of the companies attending the fair has maintained its own identity stand, finding a common service factor in the central ‘lounge bar’.”

Was the decision of the Group companies to sell all their shares and reinvest in Altofare dictated by a contingent crisis situation or by a vision that anticipates the future of Italian entrepreneurship?

“Most of the acquisition transactions were carried out in 2022, before the crisis. Altofare companies will continue to live by their own lights. Even though they have sold their shares, the respective entrepreneurs have reinvested part of the capital in the holding company by remaining as managing directors. Altofare is an umbrella and support that needs the ideas and knowledge of the individual member brands. We are trying to network, to create a platform available to our clients based on efficiency, performance, service. We want to be an evolved company that acts responsibly and sustainably. The current phase of market immobility does not worry us because the time horizon of our investment is long term. We are taking advantage of this ‘dry spell’ to ‘clean up’ all the processes that do not work.”

What are the aims of the Altofare Academy project?

“The Altofare Academy project is related to the training of our employees and entrepreneurs, with the aim of creating a strongly empathic team also through team building initiatives. With regard to the managerial part, we are designing a Management Training program with courses and experiences in different roles ranging from communication to the development of soft skills, so that the managers of the future will be able to enhance their employees and make them perform at their best. Lastly, we have made agreements with a number of technical institutes within the framework of alternating school-work projects, a long-term strategy aimed at training and induction into the company of those skilled workers who are the custodians of Made in Italy and are in danger of becoming extinct.”

What has been the reaction of the luxury brands so far?

“In generaI they are all watching us very carefully. Some have already realized the value of the project; others fear the potential risks of the change. They are afraid of losing the operational flexibility of the supply chain or of having no more intermediaries, instead Altofare is building a customer centric model entirely based on satisfying their needs. In my mind, it is crucial to be able to demonstrate skills and competences in the field, but this takes time. I am calm and positive because I am absolutely aware of what I am achieving.”

Davide Aicardi, Group Chief Executive Officer of Altofare

Altofare’s ‘lounge bar’ at Lineapelle

The aim of Altofare Group’s governance is to maintain and cultivate the distinctive characteristics of each company by putting them into a system according to a code of shared values, collected in the Code of Ethics of the group and formalised following the common benefit aims within its Articles of Association. With the birth of the Altofare Group, a close business synergy between all the companies is realised, for a strong horizontal integration of them.

Below are the companies that are now part of the new platform.

Industrie Testi

A company specialised in the production of jewellery and accessories 100% Made in Italy for the most important fashion houses. Founded in Empoli (FI) in 1999 by Alessandro Testi – designer of the group and creator of the historic fashion jewellery brand Rebecca – the company has maintained the entire production process in its Italian headquarters in the interest of uncompromising quality.

IAB (Industria Accessori Bigiotteria) (Jewellery Accessories Industry)

Excellence in the production of accessories for leather goods. Since 1972 the company in Campi Bisenzio (FI) of the OBI Group has been moulding metal to transform it into unique pieces for fashion and luxury, 100% Made in Italy.

OBI (Officina Bigiotteria Italiana)

One of the main Italian players in the luxury jewellery sector. A small family-run company founded in Florence in 1958 by Giancarlo Boncompagni, the group has evolved over the years to conquer the international catwalks of high fashion through sophisticated and flexible processing of noble

Conti & Vannelli

Excellence in the production of metal accessories for leather goods. Founded in 1961 in Florence as a small engraving workshop, today the company collaborates with high fashion companies that desire products of the highest quality, through innovative technologies capable of exalting the value of manual workmanship, acting in compliance with the principles of resource conservation.

Above, accessories created in acrylic from the collaboration between Tacchificio Monti and Lampa

Tacchificio Monti

A full-cycle company, from the initial design to the finishing of the moulded product, and reference partner of the most important fashion houses for the production of top-quality heels, soles and accessories for footwear. Founded in 1962 by the intuition and passion of the Monti family, now in its third generation, the Italian group based in Marzabotto (BO) combines cutting-edge technology and craftsmanship for flawless processing of wood, metal, plastic and resins. “We are very excited about the new partnership,” Lara Monti tells Lineapelle. “With the Altofare Group we share the same values of excellence, quality and innovation. Moreover, joining the Group gives us access to additional resources and expertise, which will be crucial for the future development of the company. We want to consolidate our position in the luxury market and the synergy with Altofare will give us the strength to face the challenges of innovative projects.”

Lampa

A leading company in the market for resin and plastic accessories and costume jewellery for the luxury sector. Having passed the 50-year mark since its foundation in 1972 by Dorino Bertoli, the company from Grumello del Monte (BG) continues on its path of growth and innovation at the service of luxury fashion houses. The business paradigm of the group with its entirely Made in Italy production is now profoundly linked to the theme of sustainability. “We are proud to have become a Certified B Corp® in 2020,” says the company, “the first in the high-end accessories sector. We aim for a production system with a low environmental impact: the latest generation of machinery saves 40 per cent of energy, more than 15 per cent of the energy used comes from renewable resources, and in 2021 we installed a new closed-circuit water system to reclaim water. In 2022 we will have GRS certification for the use of materials from recycling processes. In addition to our processing waste, we use plastics from reclaimed automotive scrap or nylon from discarded fishing nets or old carpets. Our bio-plastic – created through the polymerisation of castor oil, an entirely renewable raw material – offers the same technical performance as traditional ABS, while helping to significantly reduce CO2 emissions into the atmosphere.”

P.F. Pressofusioni Fiorentine e SCAF

Both companies guarantee a raw metal (zamak, brass and steel) production capacity among the highest in the luxury accessories market.

Since 1995, P.F. Pressofusioni Fiorentine has represented excellence in the die-casting sector of small metal parts and accessories for high fashion and beyond. The company in Campi Bisenzio (FI) designs moulds for both zamak and brass die-casting. It also makes moulds for plastics and aluminium according to customer requirements in the composition of a hybrid product. pf-pressofusioni.it

Based in Scandicci (FI), SCAF is a company specializing in micro-pressure die-casting of zamak and hot stamping. Founded in 1948 by the Masoni family, still at the helm today, SCAF is recognized as one of the best stamping companies in Europe by important international clients that it supports in all phases of metal product processing, from design to final production.

Forza Giovane Art

Centre of excellence for embroidery and special fabric embellishment. The creative and productive world of Piergiovanni Vitalini, founder of the company (known as Piero Forza Giovane to everyone) in Colli al Metauro (PU), is concentrated in-house to guarantee an authentic Made in Italy at the service of haute couture companies that desire top quality products and finishes. With a personalised service, Forza Giovane is a partner of the most important luxury brands.

On the right, a jewel created through the collaboration between Griste and CDC Luxury Chains

Griste

A jewellery company for footwear and accessories since 1975. Originality, commitment, dedication and passion are the ingredients of the success of the company founded by Guido Burattin and now managed by his children Alberto and Letizia. The historic company from the Veneto region of Villatora di Saonara (PD) holds high the Made in Italy banner throughout the world, drawing on the heritage of ideas it keeps in its archives, using only high quality raw materials and accompanying its clients in their search for the perfect element to make their creations unique.

CDC Luxury Chains

One of the major players on the world market in the supply of chains for the most important brands in the fashion&luxury sector. Since its origins, the core business of the company based in Campi Bisenzio (FI) has been linked to the mechanical and manual production of ornamental chains in non-precious metals. Stylistic research and product development are one of its distinctive features, aimed at offering new creative ideas to the design offices. An in-house laboratory dedicated to quality tests on chains and finishes monitors and certifies the durability, non-toxicity and resistance of the articles produced.