Silvateam increases its package of eco-friendly technologies by acquiring the German company wet-green, while Ecotan® kicks off the collaboration with the Italian brand Эneark1991, which launches the first line of completely recyclable sneakers.

Breaking news in San Michele Mondovì (Italy). Silvateam, world leader in the production of vegetable tannins, has acquired the German wet-green GmbH, based in Reutlingen, inventor of the patented Olivenleder® technology. The union of the two companies represents a milestone in the path towards sustainability of the tanning industry worldwide. Olivenleder® has developed a unique solution in the world by producing a very high-quality extract from olive leaves. This sustainable tanning technology integrates perfectly with Silvateam’s Ecotan® biocircular system and gives rise to an unprecedented synergy.

Silvateam, celebrating its 170 anniversary this year, works in the leather, food ingredients, animal nutrition and biomass sectors. The Piedmont-based company is at the forefront of 100% metal-free Ecotan® tanning solutions, based on natural tannins and biopolymers, and the acquisition of Olivenleder® strengthens this vocation.

The synergy of the two technologies gives life to Ecotan® Advanced, a new era for natural tanning. The combination of chestnut tannins and olive tree extract offers tanneries an even wider and highly performing range of formulations, in harmony with the environment and respecting the health of workers and consumers.

We talked about it with Alessandra Taccon, Ecotan® Project Director, and Massimo Gotti, Silvateam’s Marketing Manager.

What’s new for the current year and how does the acquisition of Olivenleder® follow your attention to the environment?

“Ecotan® is going through an extraordinary year, full of great news. Not only for the countless ongoing activities, but also for the acquisition of Olivenleder® by Silvateam, which represents an important evolution in the leather tanning industry. With a keen attitude towards the environment, Silvateam becomes the home of green technologies that respect men and the planet. The acquisition of the German brand, which is very close to Ecotan® in terms of features, technology and values, strengthens our position in the marketplace. Ecotan® boasts a network of over 40 tanneries worldwide, and new tanneries are continuously joining the project. This operation will let us further expand our network and offer customers a wider range of innovative and sustainable solutions. We called it Ecotan® Advanced.”

What are the features of Ecotan® Advanced and how is it in line with Silvateam’s sustainable philosophy?

“According to our philosophy, Ecotan® Advanced combines the new generation of solutions free of chrome, metals and other potentially hazardous substances, with completely bio-based ingredients. As a matter of fact, it offers a pre-tanning based on 100% olive tree extract deriving from waste material from olive tree pruning. This biomass, which would otherwise be burned with consequent CO₂ emissions and oxygen consumption, is instead reused to create an innovative and environmentally friendly product. The production of the extract will be mainly carried out in Italy, in the heart of the Mediterranean, cradle of olive cultivation. This will let us reduce the environmental impact associated with the transport of raw materials and strengthen Silvateam’s bond with the territory. With Ecotan® Advanced, Silvateam further establishes itself as a leader in the sustainable tanning sector by offering a new alternative to meet eco-compatibility and bio- circularity needs.”

What are the advantages of acquiring wet-green?

“The synergy between Silvateam and wet-green offers mutual benefits that go far beyond the technological sphere. wet-green will first of all have the possibility of integrating Silvateam formulations into its offer and to reinforce its position through Silvateam’s global network. Furthermore, it will have access to our experience throughout the whole production chain: from the production of the extract to the supply chain, the technical organization and the sales network. On the other hand, Silvateam will have the opportunity to enlarge the message of sustainability of chrome-free and GDA-free leather, already promoted with the innovative Ecotan® project, thus increasing visibility and consolidation in the market.”

What are your strategies to take advantage of this new synergy and spread your business into new sectors?

“Our priority is to bring together the know-how of the two brands to enter and consolidate our presence in the automotive market. In addition to the brands already served by Olivenleder® such as Audi, Porsche and Skoda, in 2024 the first car models made with the Ecotan® biocircular leather will be released; at the end of its life, that leather can be transformed into biofertilizer reducing the environmental impact and CO₂ emissions. Furthermore, this synergy also promises to be advantageous for the fashion and leather goods sectors which are approaching with growing interest at bio-based recyclable materials in line with zero-waste logic.”

How is the automotive industry responding to Ecotan®’s next-gen leather?

“The automotive industry has already implemented the concept of transition towards metal-free leather and, in general, towards the eco-design of the product: many brands are already committed to the sustainable approach for the entire design in which materials play a key role. The sector, with the advance of hybrid and electric systems, is turning towards innovative directions, but a transversal theme that is also increasingly engaging the automotive world is the second life of all components. It therefore becomes essential to start drawing a second life map with all the options of these materials. With this in mind, Ecotan® leather is tested from the beginning, before being placed on the market, to offer biocircularity models, ranging from biofertilizer, to compost and biodegradability. It’s called repurposing, that is, finding a new purpose, a new use.”

Who are your main partners?

“We have many, unusual for our sector but great contributors of ideas. Fertilizzanti Certaldo (fertilizers) and, for example, the University of Pisa. Moreover, we are collaborating in particular with Ars Tinctoria, a team of professionals specialized in organic analytical research and development of sustainability protocols based in Santa Croce sull’Arno in Tuscany (Italy). Our circularity goal is to give a second life to leather, which in itself is a by-product of the food industry. In this way, we give added value to the waste resulting from cutting bags, accessories and footwear which, instead of being incinerated in disposal centers, become ingredients for other supply chains. These are enormous scrap volumes, if you consider that on average only 50% of leather is used in luxury; therefore, we bring resources back into nature that can become precious soil nutrients, including the chestnut tannin.”

Biocircularity is…

“Biocircularity is the fundamental principle of Ecotan®. As we often remind in our international conferences, such as the last one held during the APLF in Hong Kong last March, the European regulatory evolution of the concept of eco-design will require a substantial rethinking of product making. The versatility of our technology, with its different second-life models, facilitates this process. Each market has its own dynamics and in some a type of recycling will be easier than in others. We are ready with multiple opportunities.”

What is the final goal?

“Return the resources borrowed from nature and promote a sustainable future for new generations. We cannot just keep on consuming, mistakenly thinking that resources are infinite.”

What is the challenge for the industry in designing completely circular and recyclable products?

“Over 24 billion pairs of sneakers are produced every year around the world and quickly end up in landfill. The industry today is asked to make an important commitment: to reverse the trend, designing products, such as shoes, bags and sofas, that are easily dismantled and recyclable. The different parts must be able to be separated and reused appropriately. The evolution of the market is very rapid – we saw several examples of circularity at the Salone del Mobile during the Milan design week that has just ended – and the Ecotan® community, made up of tanneries, brands and professionals in the leather world, wants to act as an accelerator of the process. Our project, born only three years ago, aims at closing the circle.”

How is the “closing of the circle” achieved?

“We test every phase of the leather production process, from pre-tanning to finishing, to guarantee its complete recyclability in nature and to enhance its end- of-life. It is the finished leather, not just the crust, that must be in harmony with nature and this represents the key selling points of the Ecotan® test protocol.”

Completely recyclable footwear: dream or reality?

“That’s a concrete fact. A recent example is the launch of the eco-sustainable shoe line designed by our partner Sneark1991 which will be showcased at the upcoming Pitti show in June. This young Italian brand, founded by a Sicilian architect-designer, has created its footwear using completely recyclable materials and Ecotan® leathers supplied by four affiliated tanneries: Hashtag, DVS, Camaleonte and Volpi. The shoes also feature a totally biodegradable sole produced in France. Not a dream, therefore, but a real change, a revolution!”

The eco-sustainable shoe line designed by Ecotan®’s partner Sneark1991, completely recyclable

Alessandra Taccon, Ecotan® Project Director, and Massimo Gotti, Marketing Manager Silvateam

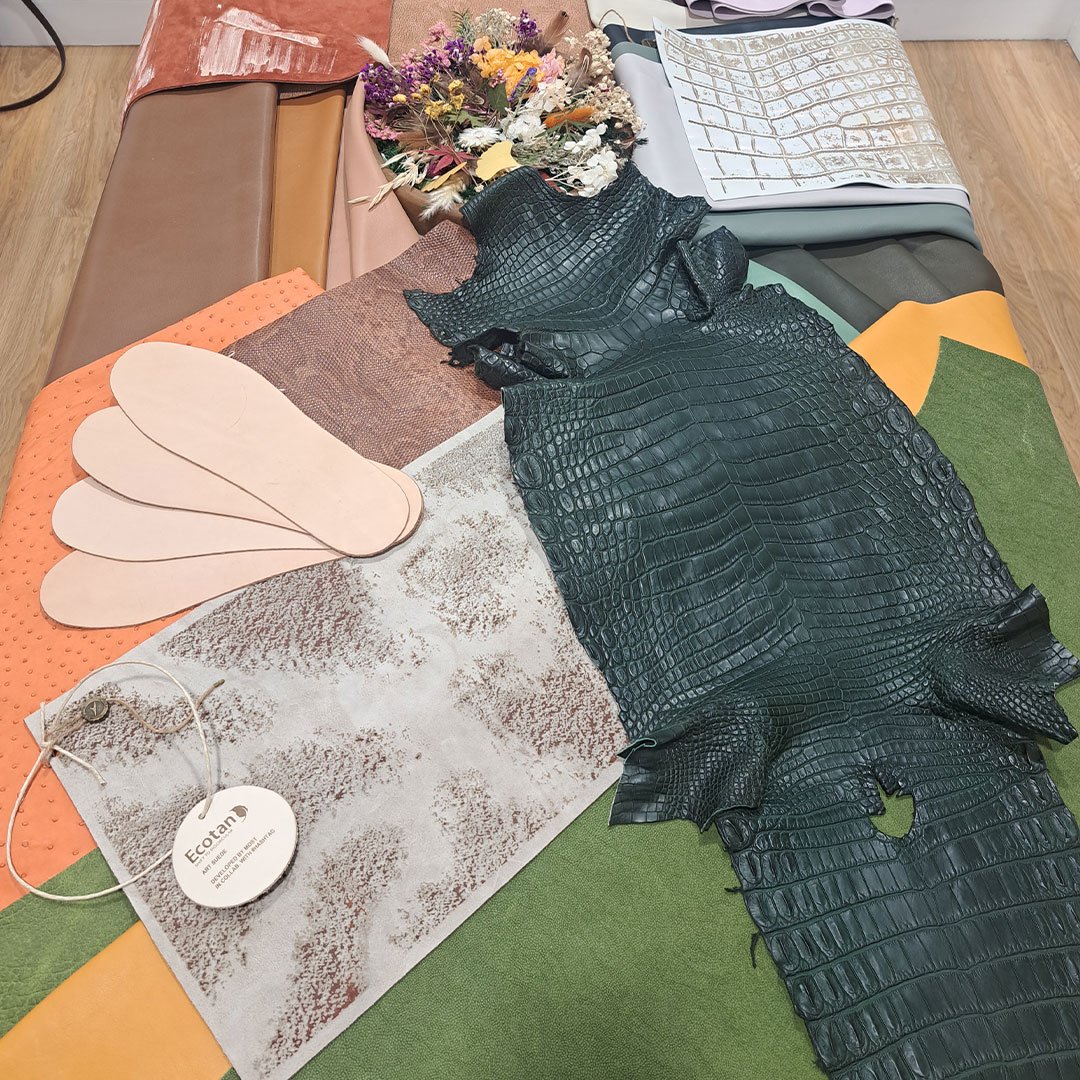

Silvateam’s stand at the latest edition of Lineapelle: this year, it boasted a space devoted to fashion trends