A regular fixture at Lineapelle, Plaginsa focuses on the quality of materials, on processing versatility and on environmental safeguard.

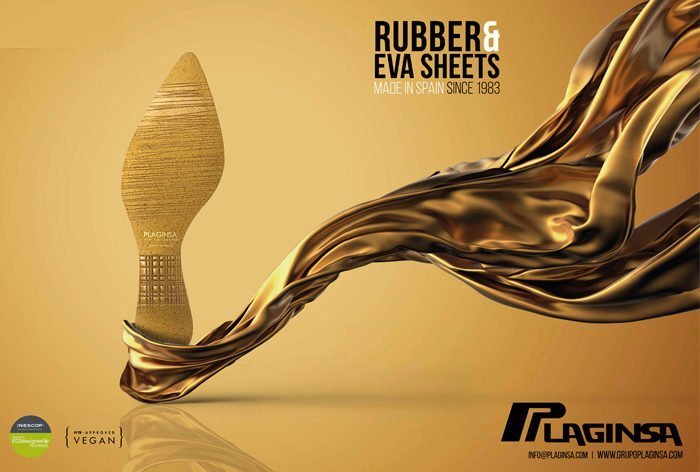

Established in 1983 by the current president Gaspar Navarro, Plaginsa aims at providing competitive, successful solutions that can meet the demands of professionals in the footwear industry, by manufacturing rubber and EVA sheets for the production of soles. Manuel Martinez, executive manager of the Alicante-based company, put in the spotlight the endless range of models, their strengths and properties – the result of more than thirtyfive years of experience in the business.

Manuel Martinez, Plaginsa’s executive manager

Manuel Martinez, what are the strategies pursued by Plaginsa in order to be competitive and to keep up with times? We provide a cutting-edge product, relying on the skills and professionalism acquired in over thirty-five years of experience in the rubber sheet sector. We have been cooperating with professional and global delivery companies able to guarantee timely services throughout Europe as well as worldwide. Each innovation is designed for those looking for an excellent price/quality ratio, a feat that has helped us become an international benchmark for the industry players.

What are the distinctive traits of your products? The lightness and flexibility of the material, resulting in the utmost comfort for the foot. Finishes’ elegance and variety, thus featuring an ample range of patterns and motifs that can be customized according to one’s specific needs. New colours and nuances that give a stylish touch to the show. All the details make the difference. For example, the finishes of the Neolite soles allow to get a leather-like effect, as realistic as possible, able to “deceive” the eye at first glance: therefore, the perfect combination between the allure of leather combined with rubber’s main qualities – water-proof, durable, resistant to abrasion, non-slip. Given the amazing success of sneakers and sports footwear, foam rubber sheets guarantee a higher level of processing versatility compared to injection moulding (the latter tied to the design and manufacturing of moulds) and this is the true business: you can get complex shapes through milling, you can rely on different thickness options, textures and shades. It all depends on the designer’s creativity. Furthermore, rubber sheets give to shoe factories the chance to focus on small-volume manufacturing as well.

What is your stance in terms of environmental safeguard? We enhance industrial processing waste and scraps by recycling and re-using them in the production cycle. The company was awarded with the PETA-Approved Vegan certification by the animal-rights association PETA- People for the Ethical Treatment of Animals: rubber and EVA sheets as well as the components used for their production are completely devoid of any animal trace. We comply with all the European restriction regulations concerning the use of hydrocarbons. We invest in machinery upgrading and in research activities: we have carried out tests on rubber sheets made by adding a percentage of either seaweeds or recycled wood. We are assessing the performances and benefits of said solutions. www.grupoplaginsa.com

Plaginsa present at Futurmoda, Alicante 11-12 Marzo Stand Nº : G13-G15