The latest PraneM innovation at Lineapelle marks a new frontier in antistatic and environmentally friendly solutions for occupational footwear

“The market is objectively declining,” Gabriele Diddi, Chief Executive of PraneM, told us at Lineapelle. “ In my opinion, this downturn is partly physiological after the post-Covid boom and partly due to the ongoing international tensions. However, operating mainly in a sector like safety, which is not affected by the ups and downs of the economy in the same way as the fashion industry, we still manage to maintain our sales volumes. We try to take an objective yet optimistic view.” This is where the two new proposals with high added value in terms of technology and sustainability come from, capturing the attention of the operators at the stand of the Prato-based company specialized in the production of technical textile materials for safety footwear.

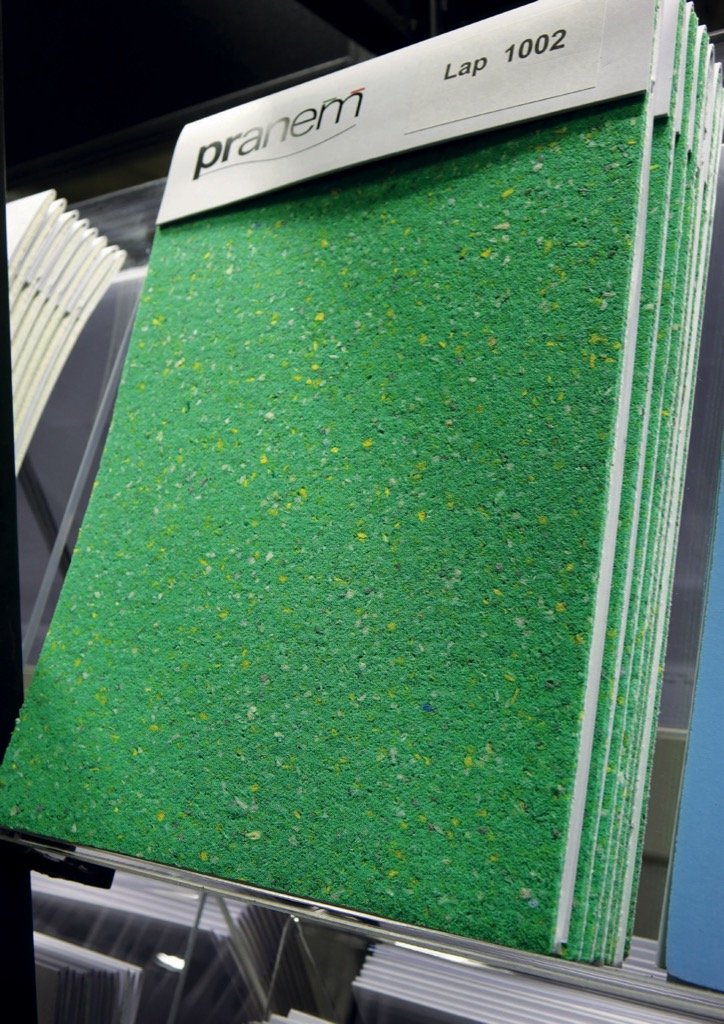

Lap 1002 is a non-woven article intended for the manufacture of removable and assembling insoles, produced with 50% recycled synthetic fibers and recycled polyurethane foam. Its substantial difference from traditional materials is first and foremost of an ecological nature: the non-use of chemical resins results in the absence of the respective waste products to be disposed of in landfills and in a reduction of both pollutant emissions into the atmosphere and energy consumption. The Lap lamination technology gives flexibility and dimensional stability to a product that is breathable, unaffected by moisture, and suitable for Strobel stitching and glued assembly.

Refa 1000, on the other hand, is the name of a conductive lining for work footwear made of embossed fabric with a three-dimensional effect, made of a continuous filament of polyester and steel. The latter ensures the dissipation of static electricity accumulated by the human body during work activity. The conductivity values are <1×105 – ESD (Electro Static Discharge) in compliance with EN ISO 20344. The knitted construction gives the lining the elasticity necessary for perfect adaptation to the shape of the shoe. The continuous filament with the porosity of the textile structure allows high breathability. Combined directly with the antistatic sole, Refa 1000 avoids the use of conductive insoles (insoles), becoming a safety element in maintaining the conductivity of the shoe throughout its life cycle.

“We specialize in the production of technical textile materials that fully meet the current market requirements for safety footwear,” Gabriele Diddi continues, “and we have always operated with a particular focus on the ecological value of recycling. All our midsole products use pre- and post-consumer reclaimed fibers. For standard articles we use fibers from the textile chain (pre-consumer) processing waste. In the case of our article Recy 2020, a non-woven midsole fabric suitable for Strobel stitching, which is also available in an anti-static Safety multicolour version, we use 100% recycled fibers from post-consumer waste, i.e. from clothing and furnishings (hence the multicolored appearance) otherwise destined to landfill. Their technical performance, as well as their resistance to stitching, assembly and use, are comparable to those of traditional materials.”

The new conductive lining for the Refa 1000 work shoe, in embossed fabric with three-dimensional effect

Gabriele Diddi, Chief Executive PraneM, at Lineapelle

The PraneM stand at Lineapelle narrates the virtuous cycle of midsole production assembly that comes from used clothing, the perfect combination of eco-sustainability and safety

Lap 1002, the new eco-sustainable article for the manufacture of removable insoles and assemblies