Silvateam celebrates a historic milestone: 170 years of innovation in the world of plant extracts and a future dedicated to sustainability.

Silvateam, a world leader in the production of tannins and other plant extracts, is celebrating an extraordinary anniversary: 170 years of history. This milestone is the result of a constant commitment to sustainability and innovation. The company, always attentive to the enhancement of natural resources, has developed a full range of environmentally friendly products that are used in a variety of sectors, from leather tanning to food, from nutraceuticals to animal nutrition. Among the latest developments, Silvateam has recently acquired wet- green® GmbH, a German company specializing in olive tree extract marketed under the Olivenleder® brand. This 100% natural product integrates perfectly with the Ecotan® biocircular tanning technology and stands out as a beacon for the development of future sustainable innovations in the leather industry. Silvateam is optimistic about the future, investing over 3% of its turnover in R&D activities and enhancing its human capital, mostly young people. A commitment also embodied by the support given to local communities and to the care for environment where its production plants are located, in Italy, Argentina, and Peru. Silvateam is a family business to be modeled after, a tangible example that combines tradition and innovation to build a more sustainable future for young generations. This milestone is just a new beginning for this beautiful reality, ready to face the challenges of tomorrow with the same passion and dedication that have distinguished it for the past 170 years. We spoke about this face to face with Antonio Battaglia, Director of the Leather Business Unit.

How have you been able to combine the legacy of 170 years of family history with this very strong drive for innovation and diversification that has led Silvateam to become a world leader in its sector?

“This is a really good question that invites us to reflect on our long journey. As a corporate history enthusiast, I remember with pleasure the 150th anniversary of the company, when I edited a book, titled “The valley of tannins”, full of documents that revealed previously unpublished aspects of our past. On that occasion, an Italian professor highlighted, as you well pointed out, the combination of tradition and innovation that has always distinguished our company. Our family joined the company some 20 years after its foundation in 1854, beginning a 170-year-long story. Chestnut tannin extract, produced since company’s origin and still one of our pillars today, represents the thread that inextricably links our tradition to innovation. Established as the world’s first tannin factory during the Industrial Revolution, Silvateam revolutionized the silk and tanning industries by replacing the use of bark and wood chips. Chestnut tannin, initially used to obtain the typical black color of nineteenth-century silk lace, soon found new applications in the tanning industry, mostly linked to the production of sole leather, between the late nineteenth and mid-twentieth centuries. The ability to adapt and innovate has always been an essential part of our DNA. Over the past two decades, the company has carried on this philosophy with dedication, developing new applications for its products in sectors such as food, cosmetics and nutraceuticals.”

Silvateam stood out by its commitment to reusing production waste and respecting the environment. What motivated you to make sustainability a key pillar of your business strategy and what are the future challenges and opportunities in this area?

“We have been really lucky to be born into a naturally sustainable company at a time in history when many other factories are having to completely reinvent their business model. Our competitive advantage comes from a product, tannin, that has accompanied mankind since its origins. As a matter of fact, tannin is a natural polyphenol that has the ability to bind to proteins, allowing animal skin to be transformed from a putrescible to a durable, beautiful and useful material for making shoes, leather goods, car seats and sofas such as Ecotan® leather. With high astringent and antioxidant power, tannin is produced by plants to protect themselves from the attack of pathogens, such as viruses and bacteria. The animals themselves take advantage of the beneficial properties of the leaves and bark of trees, naturally rich in tannin, to heal themselves and keep their intestinal bacterial flora in balance. The current rediscovery of the use of natural products in the industry is an opportunity we enthusiastically embrace. The main challenge, however, is to translate the beneficial properties that we have always known and boasted into concrete numbers. For this reason, we actively engage in research, also through collaborations with universities and prestigious private bodies, to scientifically validate our claims. Our goal is to provide our clients, whether tanneries, fashion houses or food companies, with the tools they need to communicate the tangible benefits of our green technologies to the end consumer. In this way, we contribute to creating a more sustainable and conscious supply chain that benefits everyone.”

How will the acquisition of wet-green® GmbH, a pioneer of the patented technology Olivenleder®, affect your strategy?

“Today Silvateam is a cutting-edge company thanks to its 100% metal-free Ecotan® tanning solutions. The acquisition of Olivenleder® strengthens this vocation: the philosophy behind the olive tree extract fits perfectly with our values, completing our range of solutions for sustainable tanning. As a matter of fact, this extract gives the leather unique properties: greater softness and optimal performance for use in the automotive and fashion industries. As its origin is natural and biocompatible, it will be entirely produced in our factory in San Michele Mondovì (Italy). This will allow us to optimize production costs and offer our clients increasingly high-performance and environmentally friendly solutions.”

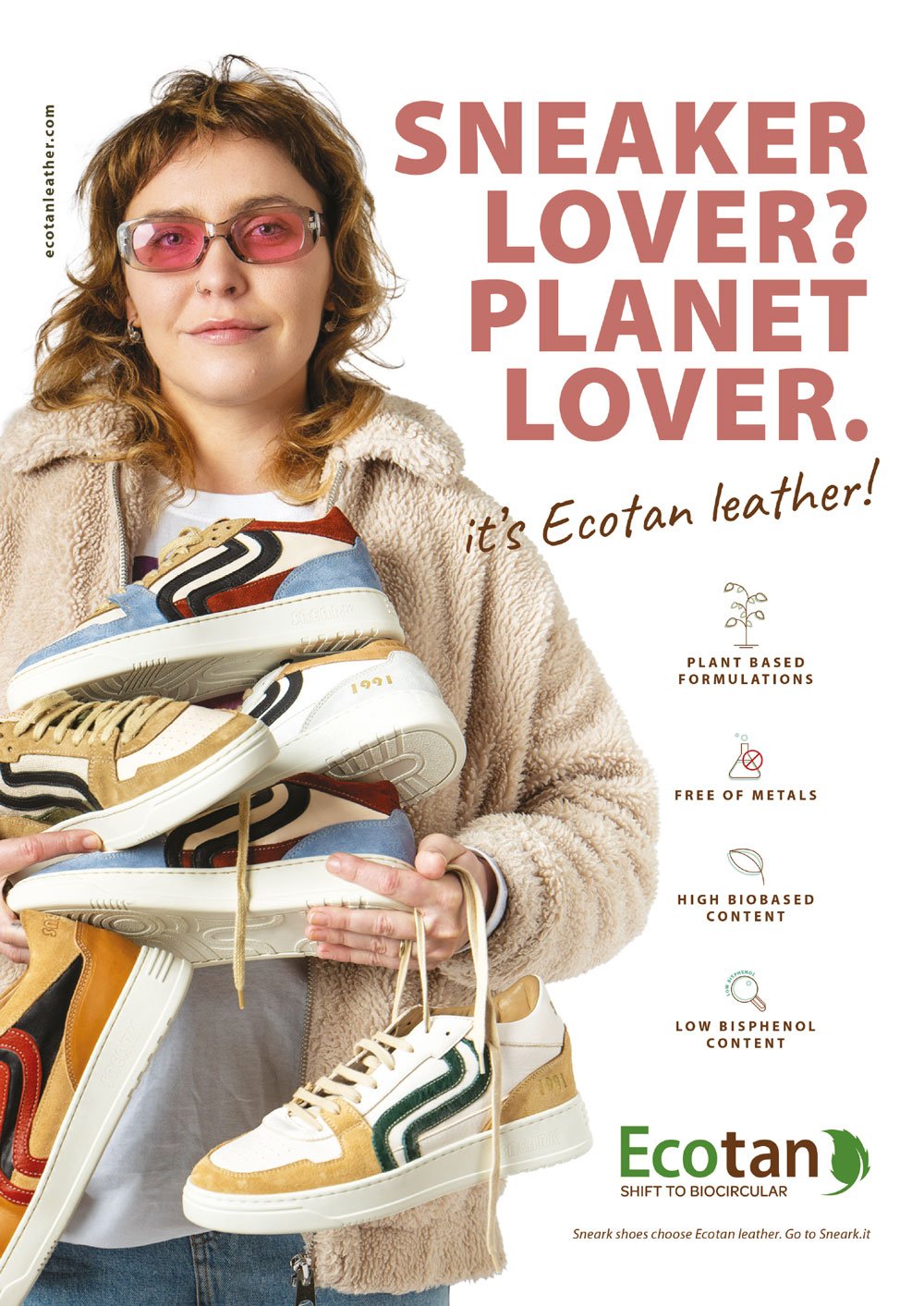

What is the latest news about Ecotan® leathers?

“Ecotan® technology is based on a natural tanning process, made with tannins from renewable and PEFC certified sources which are combined with biopolymers that are safe for humans and the environment. This innovative tanning technology not only produces high-quality, healthy, and sustainable leather but also closes the product life cycle ecologically. In fact, end-of-life leather and processing waste can be used to produce fertilizer for organic farming. But that is not all. Over the last 12 months we have assessed Ecotan® for new alternative upcycling methods such as the production of compost, biochar and other circular economy scenarios. The new second life protocol opens up new and broad perspectives for the tanning sector, encouraging “cross collaboration” between different supply chains such as fashion, agriculture, fertilizer producers and the recycling industry, to name a few.”

How does Silvateam intend to maintain market leadership beyond innovation?

“Our leadership in the industry has been achieved and consolidated over time through a strategy aimed at expanding the range of products and their applications, meeting customer needs, and completing our value proposition. Today we generate half of our turnover from applications in the food and animal feed sectors. We are optimistic about the future, convinced that in the coming years the new applications we are developing will further contribute to strengthening our leadership position. Our ability to innovate and meet market needs enables us to face future challenges with confidence and keep on creating value for our clients and stakeholders.”

Silvateam has a deep connection with the territory and its local communities. How does this bond translate into your activities?

“Our company is distinguished by its presence in remote areas of the world, where we operate to enhance raw materials of plant origin. From the forests of the Italian Alps to the deserts of Peru, passing through northern Argentina, our production chain unfolds in unique geographical contexts. While this choice leads us to be relatively isolated, it also imposes a deep responsibility to local communities. We are actively committed to contributing to their development in a sustainable way, creating job opportunities and promoting initiatives to improve the areas where our manufacturing plants are located. In Peru, for example, we have promoted eye check-ups, while in Argentina we have contributed to the purchase of school textbooks for our employees’ children. Isolation has driven us to make the most of our in-house resources, investing in the training and professional development of our collaborators. Almost all of our managers have grown within the company, through customized training paths. We strongly believe in the human potential and professional growth of our employees.”

Antonio Battaglia, Director of the Leather Business Unit.

To celebrate the significant milestone, Silvateam welcomed all employees, families and friends to its HQ in San Michele Mondovì (Italy) for a memorable day of festivities.