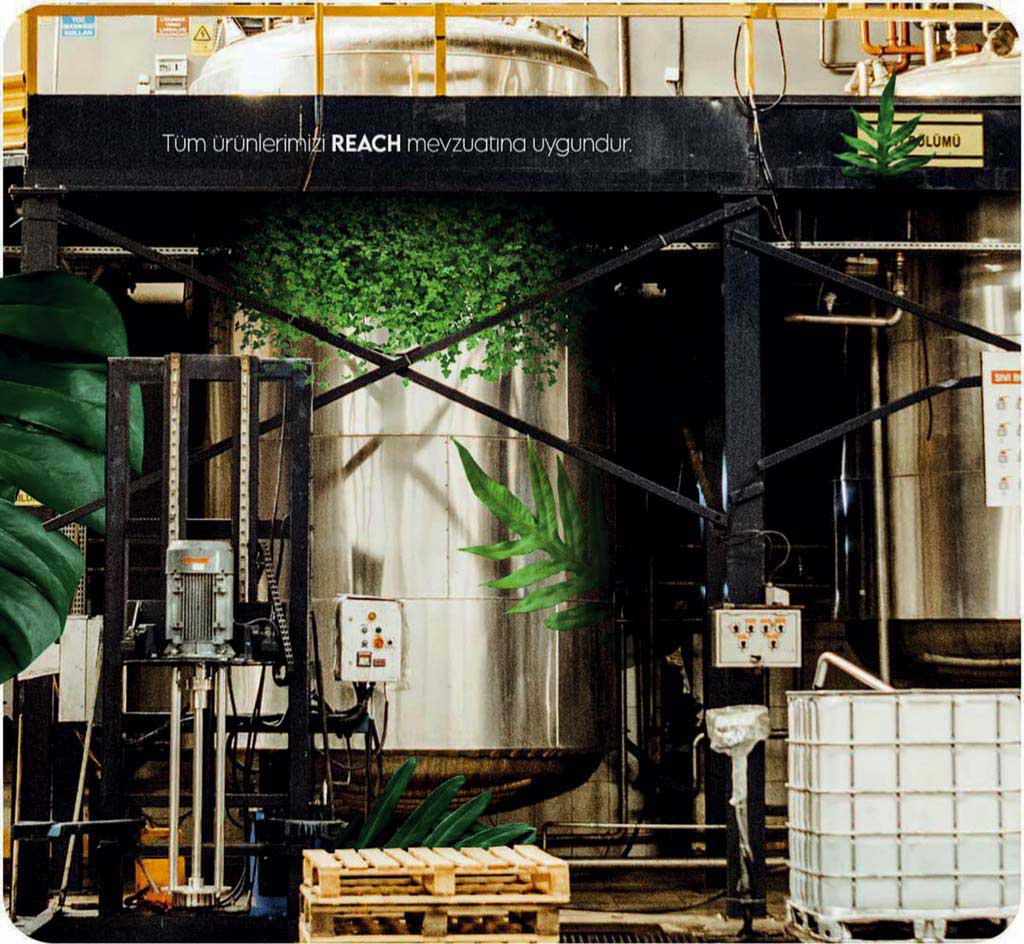

United Chemicals is making a difference in the chemical industry through its significant progress in reducing the environmental impact of its manufacturing operations.

The chemical industry is often criticized for the environmental impact of its production activities. However, there are companies that are making significant progress towards reducing their impact and promoting sustainability. This is the case of United Chemicals, a Turkish chemical company that is attracting the attention of the sector for its ecology-driven commitment. Founded in 1990 and headquartered in Istanbul, United Chemicals has established itself as one of the leading chemical companies in Turkey and has spread to several European countries. The company specializes in the production of chemical products for the textile, clothing, paper and cosmetic industries. However, what differentiates United Chemicals from other chemical companies is its strong commitment to sustainable development, through the use of only high- quality raw materials and minimizing the environmental pollution of its production processes. Its attention to sustainability also stands out in its products, which are designed to increase the durability of the raw materials they are meant for, reduce water and energy consumption during the production process and minimize the release of harmful substances into the environment. In this green management perspective, to supply its activities the company has invested consistently in technologies that use renewable energy sources, such as solar and wind power; it also managed to reduce the consumption of water and energy and to recycle production waste. Furthermore, the company carried out all the procedures to comply with all environmental regulations and collaborates with the competent authorities to improve the sustainability of the chemical industry in the area. In short, United Chemicals stands out for its focus on sustainable development and the quality of its products. Thanks to its initiatives – including the first publication of an information booklet on tanning processes “Practical Information for the Leather Technologist” intended for tannery technologists –, and to its drive towards innovation, Unichem is becoming a point of reference for the Turkish and international chemical industry. His experience shows that it is possible to reconcile industrial production with the protection of the environment and the health of people.

What were your expectations about Lineapelle this year?

“We always participate in the fair, every year, except for the year it was suspended due to Covid. Being here is very prestigious for us and we feel very lucky to be able to participate. Getting ready for this event takes months and months of intense work: from preparing all the hides, which this year have been dyed only black and red (our corporate colors), to creating special catalogs to best show our products. It is a unique opportunity to launch new items and ideas, we started working on it since November. The fair also offers us the opportunity to meet our customers, many of whom participate as exhibitors or visitors. In short, behind every event there is a deep preparation that let us present our company and products in the best possible way.”

What do you think about attending international trade fairs, which offer the opportunity to meet other players in your sector, including potential customers?

“Well, for us Lineapelle truly represents the perfect opportunity to meet our customers and other players in our sector. At each edition, we have the chance to set a series of appointments and organize meetings very easily. Furthermore, we to warm up, have dinner together, socialize. I think it’s a unique opportunity to meet, catch up on the latest industry news and make new relationships. After Covid, traveling has become much more complicated, especially last year, and we have been set apart from our customers for two years. Therefore, participating in events such as Lineapelle becomes even more precious and meaningful for us today.”

This year you have launched a new useful tool: a booklet entitled “Practical Information for the Leather Technologist”. What exactly is it and what’s its purpose?

“This booklet collects all practical and useful information for leather technologists, a very valuable tool that we are giving away for the first time this year. It guides the reader through the leather tanning processes, starting from the farms up to the finishing, covering both the wet-end and the finishing phases. The booklet also presents comparative information and methods of process and quality control as well as environmental issues of the leather industry. Our company is strongly committed to environmental protection and we have launched several projects in this direction. The book also talks about our products and how they can be used in leather manufacturing processes.”

Let’s go into detail…

“This document contains selected information on different aspects of leather and is divided into six parts. Part-1 provides a general overview of statistics on available livestock and raw materials, animal diseases and ante-post-mortem generated defects. All stages of the wet process, from steeping to dyeing, are briefly reviewed and essential data for each stage is included. A complete general finishing system and the products used are rated for users of this document. Also, in this part, the company’s proprietary chemicals are briefly mentioned at the appropriate process steps. More detailed information can be obtained from the datasheets and model sheets. Part-2 contains definitions of “ancient” and lesser-known leathers and information on the tannery machinery, on the equivalence between the different items, on the shrinkage temperatures of different leathers, on the distribution percentages of the leathers produced all over the world and related costs of the tannery. Relevant comparative topics are included for interested users. Part-3 is dedicated to practical methods of tanning processes control. Practical solutions using basic reagents, indicators and classic laboratory equipment are illustrated, selected from different process cases. Part-4 briefly discusses current environmental issues and the types of waste available, waste treatment, safer processing methods, environmental protection and pollution controls. The tannery water discharge limits are also briefly taken into consideration. Part- 5 is dedicated to the limited chemicals used in leather tannery. Finally, Part-6 includes the essential chemical components, general data on preparation of buffer solutions and indicators. Conversion tables relating to water densities, thicknesses and hardness are also provided. The required limit values for the different hides are included. Finally, references to selected books on skin technology and chemistry have been added for curious readers and researchers.”

That’s a lot of information…

“Yes, we wanted to create something really useful. It was not possible to include many other practical information, provided in other books or manuals, due to the limited layout of the document, but all our experience is always available to our customers and whoever will become a one.”

UNITED CHEMICALS – unitedchemicals-co.com

Can and Ladin Kaleli, second generation at United Chemicals